Article: EngineeringTalk.com

Tactilus allows research and design engineers to quickly and precisely test and correct the surface contact and pressure distribution between the heat sink and semiconductor in embedded applications.

Tactilus® allows research and design engineers to quickly and precisely test and correct the surface contact and pressure distribution between the heat sink and semiconductor in embedded applications.

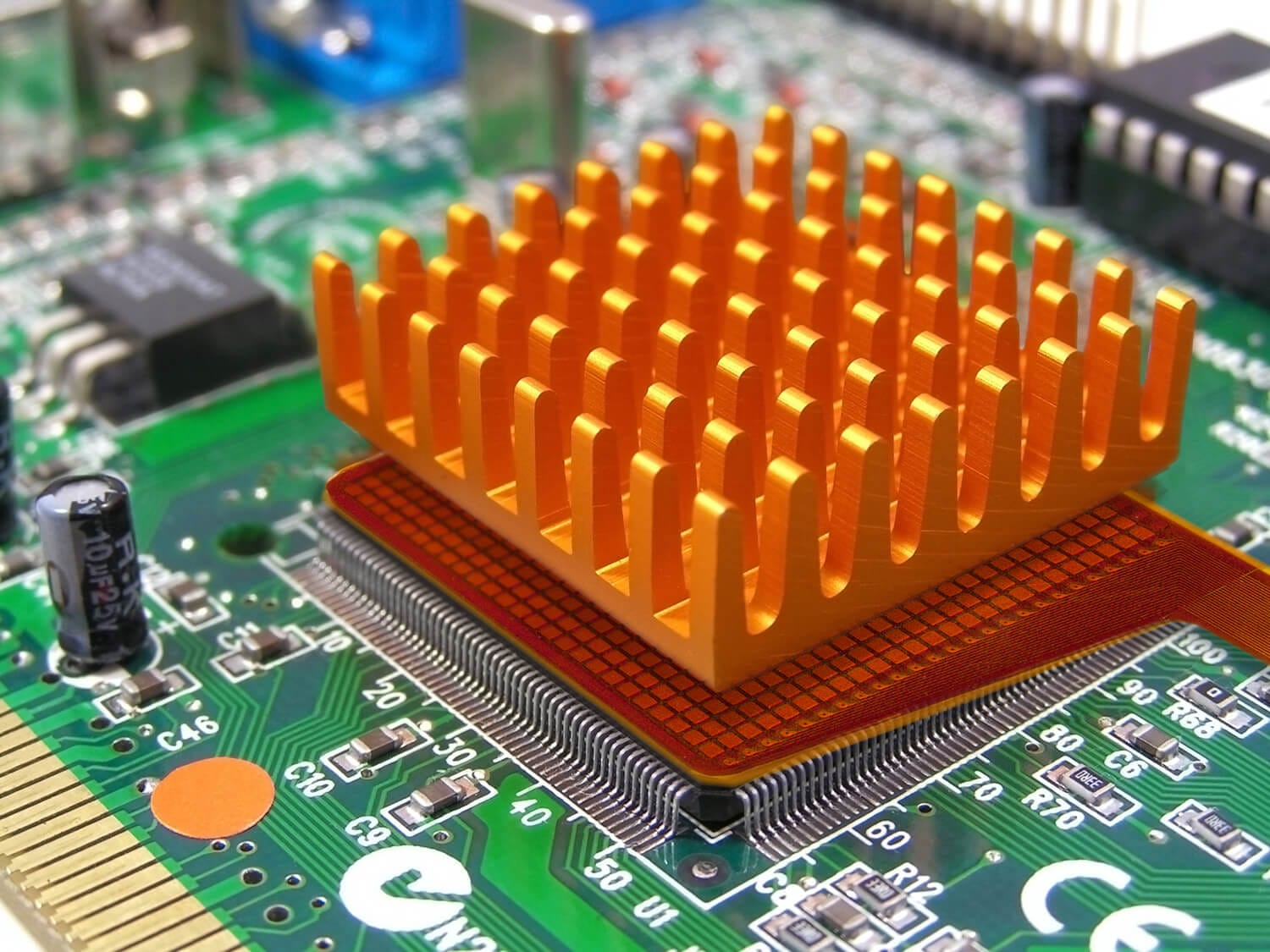

Even a slight warping of the heat exchange structure or reduction in surface contact area can have a profound effect on cooling efficacy.

If the pressure distribution is not uniform, heat conduction will be low and the electronics may overheat. With the Tactilus® heat-sink analysis system, engineers can visualise actual contact forces and pressure-distribution data on the circuit board components.

As the mounting screws between the CPU and the heat sink are torqued, Tactilus® maps and measures the changing pressure distribution between the mating surfaces and displays it through its software. The heat sink interface can be tested, manipulated and repositioned in real time, speeding the trial-and-error process and eliminating the need for additional assembly.

Tactilus® also provides the pressure data needed for FEA simulation predictions.

The Tactilus® sensor is flexible and only 0.015in (0.38mm) thick, allowing it to be placed between the CPU and heat sink without affecting the assembly. The sensor pad has 625 resistive sensing points arrayed on a 25 x 25 grid, with a total sensing area of 2 x 2 in. The scan speed is up to 1,000Hz and the operating pressure range is 0 to 100psi (0 to 7kg/ cm2).

Tactilus® collects and processes sensor data using powerful Windows-based software that performs the following tasks: creates pressure-versus-time graphs and histograms; performs 2D, 3D and 360deg image rendering and region-of-interest scaling; displays maximum, minimum and average pressures, and does force integrations; and prepares reports through export to Excel, ASCII or Access formats.

The Tactilus® sensor system will endure hundreds of diagnostic uses on different heat sinks with consistent repeatability and is highly resistant to electromagnetic noise, temperature and humidity fluctuations.

Accuracy is +/-10 per cent, repeatability is +/-2 per cent, hysteresis is +/-5 per cent and non-linearity is +/-1.5 per cent.

The versatile Tactilus® Sensor System can be adapted to virtually any measurement modality or application to see surface pressure distribution in real time. It is used to map and measure surface pressure distribution at the interface of tire tread footprints, door seals, heat seals, fuel cells, printed circuit boards, flat-panel displays and wafer polishing.

Sensor Products provides off-the-shelf and custom design solutions.

In addition, Dynamic Link Library (DLL) files and the Graphical User Interface (GUI) can be tailored to the customer�s specifications