Schedule a Live Product Web Demo

Click Here To View Our Off-The-Shelf Sensor Solutions

What it does

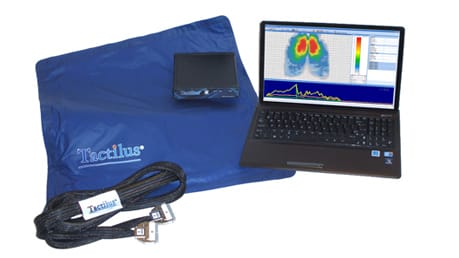

Tactilus® allows the user to capture and record pressure conditions occurring in between any two contacting or impacting surfaces in real time. The paper-thin Tactilus® sensor is actually placed at the contact interface where it records and assimilates both pressure distribution and pressure magnitude on your Windows® based computer.

Tactilus Sensing Element, Hub and Software

The innovation

Exciting advancements in conductive textiles have allowed us to develop a sensor that conforms better to your surface than ever before. Not only does the sensor conform better to curved surfaces but it stretches to alleviate shearing affects caused by shifting contact surfaces – an innovation that no other sensor company can touch! By biomimicking human skin we’ve taken surface contact pressure measurement to a whole new level.

Tactilus® now has all the electronics safely encapsulated on the sensor element itself. The Tactilus® sensor consists of a series of interlaced lines that create a matrix with as many as 16,384 unique sensing points. Tactilus® Windows® based software communicates with the sensor up to a theoretical 1,000 frames per second – fast enough for impact force measurement. For users desiring direct interfacing with their own control software Sensor Products can supply an API.

Industries we serve

Aerospace

composite layup, fuel cell, lamination

Electronics

BGA, connector, fuel cell, heat sink, lamination, LCD bonding, wafer bonding/polishing

Packaging

nip impression, heat sealing

Ergonomics

biomechanics, body mapping

Automotive

brake pad, clamping, clutch, fuel cell, gasket bolted joint, impact study, lamination

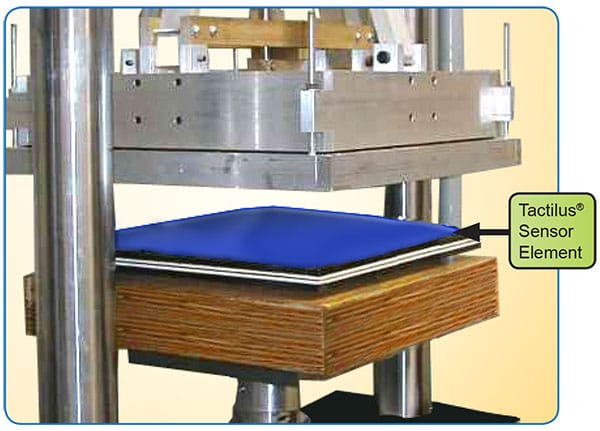

Tactilus® sensor element placed on a lamination pad

Schedule a Live Product Web Demo

Schedule a Live Product Web DemoDownload

- Tactilus

- Tactilus Series Comparison

- Tactilus Object Detection Sensor

- Tactilus Now NIST Traceable

- Tactilus Free Form

- Tactilus Free Form – Temperature

- Tactilus Power of Image Processing

- Private Branding

- Tactilus High Temp S-Series Sensor

Applications

- Brake Pads And Calipers

- Bolted Joins

- Bolt Switch

- Door Seal

- Golf

- Heat Seal

- Heat Sink

- Impact Sensor System

- Lamination

- LCD & Flat Panel Display

- Metal Welding

- Nip Impressions

- Podiatry

- Printed Circuit Board

- Seating

- Soil-Structure Interaction

- Solid State Switches

- Spray

- Squeegee

- Squeezable Tubes

- Temperature Mapping

- Ultra Sensitive Applications

- Ultrasonic Welding

- Wafer Polishing

- Windshield Wiper

Products

Articles

- Food Packages (Italian)

- Automotive Products Finder

- Packaging Machinery Technology

- Tube News

- Food Marketing & Technology

- Alimentacion

- Design World

- The Daily Record

- Ingenieurs de l’Automobile

White Papers

- Use of weight-bearing MRI for evaluating wheelchair cushions…

- Estimating Vertical Stress on Soil Subjected to Vehicular Loading

- Factors Affecting Human Comfort Response to Garments

- The Influence of Environmental Temperature…

- Response of Endothelial Cells to Stressors…

- Real-time Continuous Monitoring of Sub-dermal Tissue…

- Pressure-Sensing Devices for Assessment of Soft Tissue…

- Strain and Stress Distributions in the Gluteus Muscle…

- Assessment of mechanical conditions in sub-dermal tissues…

- Elementary CNN Algorithms And An Experimental System…

- The Effect of Body Fat, Aging and Diabetes on Vertical…

- Revolutionary Advance in Reducing Pressure Ulcers on Patients…

- Natural and Simulated Pointing

- Analogic CNN Algorithms for Textile Quality Control Based on Optical…

Benefits of Tactilus®

- Highly conformable and elastic sensor.

- True calibration. Now NIST traceable.

- No cumbersome external electronics. They’re safely built into the sensor.

- No training required. Hit the ground running.

- Durability like no other sensor.

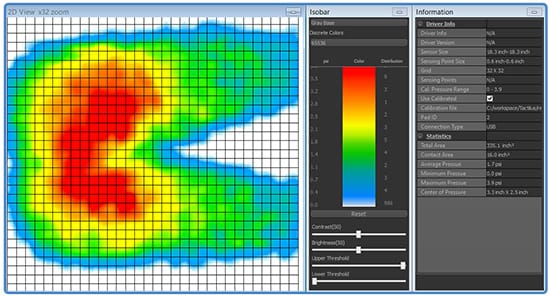

Tactilus® software assimilates complex data into easily accessible graphics

| Sensor Specifications | |

| Technology | Piezoresistive |

| Pressure Range | 0.1 to 200 PSI (0.007 to 14.1 kg/cm2) |

| Matrix Size | Up to 64 x 256 lines |

| Thickness | From 12 mils (0.3 mm) |

| Mat Sensor Size | Customizable up to 150″ (381 cm) |

| 1Scan Speed | Up to 1,000 hertz |

| Min Sensing Point Size | 0.188 in2 (1.21 cm2) |

| Stretchability | Up to 158% |

| Accuracy | ± 10% |

| Repeatability | ± 2% |

| Hysteresis | ± 5% |

| Non-linearity | ± 1.5% |

| Calibration | NIST Traceable |

| 2Software Compatibility | Windows 8, 7, XP |

1) Only for some configurations with fewer sensing points.

2) An API can be provided to users who need to real-time connectivity to their own software.