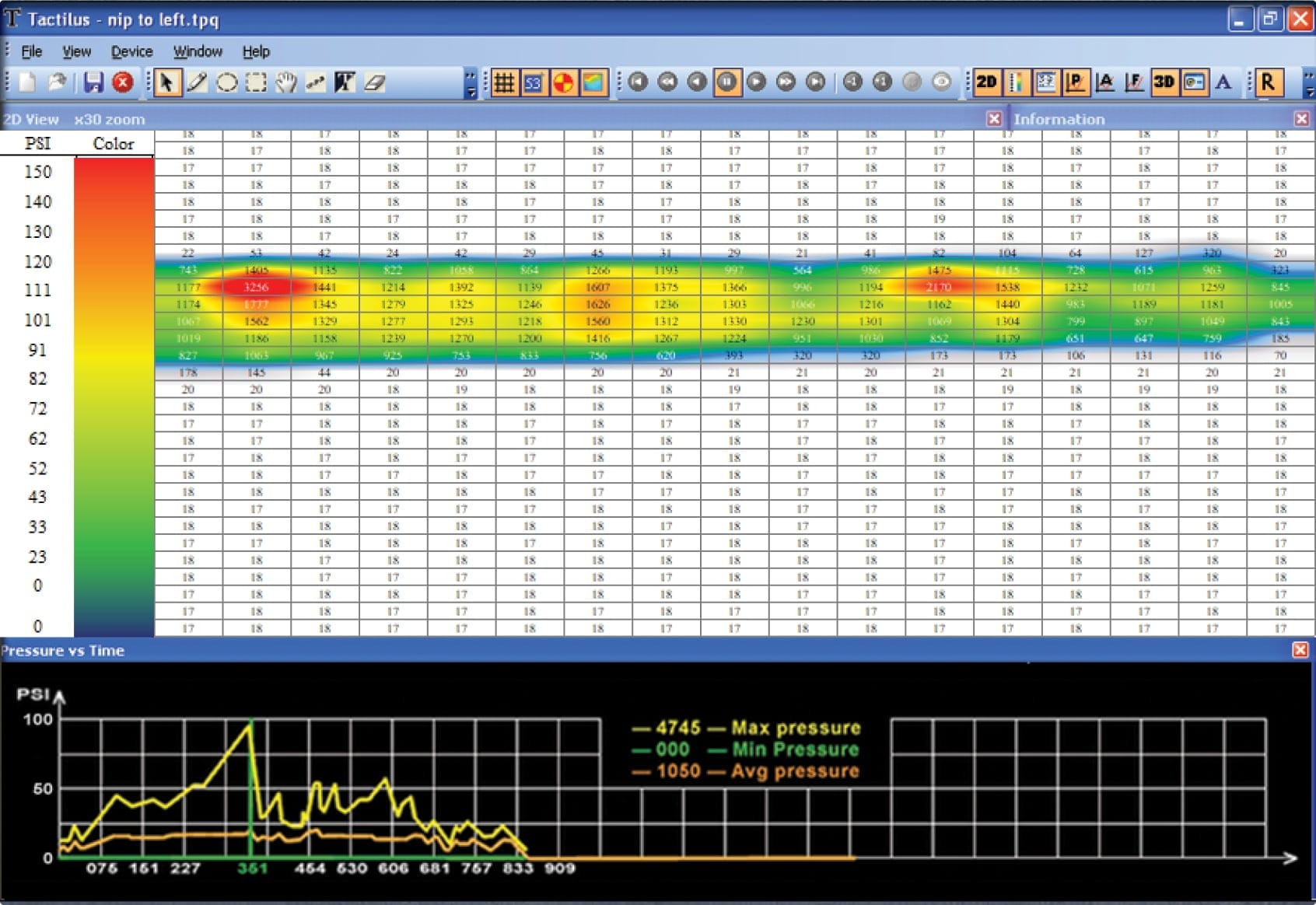

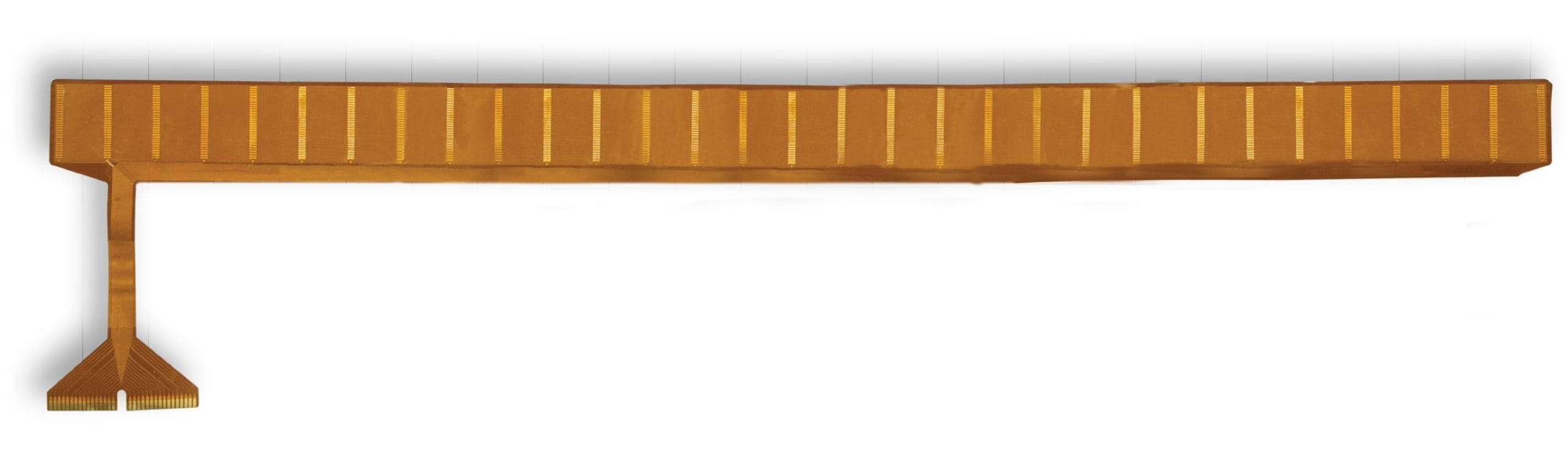

The Tactilus® nip measurement tool captures nip pressure and parallelism information from between any two mating rolls whether the surface is rubber, composite or metal. Tactilus® is a real-time, static (rollers not rotating) sensor system that quickly and effortlessly allows for rapid nip contact pressure and distribution measurement. Even an inexperienced user will quickly gain valuable insight from Tactilus®. In just minutes, Tactilus® can be deployed across your nip interface and capture a wealth of valuable data. The sensor is only one element of the overall Tactilus® system. Our user-friendly Windows® compatible software assimilates the information captured into intuitive, easy to interpret reports and images.

The Innovation

The exciting advancements in Nano-materials have allowed us to introduce the world’s first nano-polymer based tactile surface sensor. With greater temperature resistance, more accuracy, less drift and better repeatability the user now can perform surface mapping analyses with greater confidence than ever before.

What It Does

Tactilus® allow the user to capture and record pressure conditions occurring in between any two contacting or impacting surfaces in real time. The paper-thin Tactilus® sensor is actually placed at the contact interface where it records and assimilates both pressure distribution and pressure magnitude on your Windows® based computer.

Benefits of Tactilus

Improving product yield

Extending cover life

Sharply reduced machine downtime

Assuring compliance with GMP and ISO regulations

| Specifications | |

| Technology | Nano-tube composite |

| Surface Pressure Range | 0 – 150 PSI (0 – 10.5 kg/cm2) |

| Grid Size | 32 x 32 |

| Sensing Points | 1,024 |

| Total Sensing Area | Customizable up to 32 x 86 in. (81 x 218 cm) |

| Scan Speed | Up to 800 fps |

| Spatial Resolution | Custom from 0.5 in (1.3 cm) |

| Thickness | 16 mils (0.4 mm) |

| Accuracy | ± 10% |

| Repeatability | ± 2% |

| Hysteresis | ± 5% |

| Non-linearity | ± 1.5% |