Article: Shine Magazine

Tactile pressure indicating film provides a simple cost-effective method of process control and monitoring of solar module production equipment.

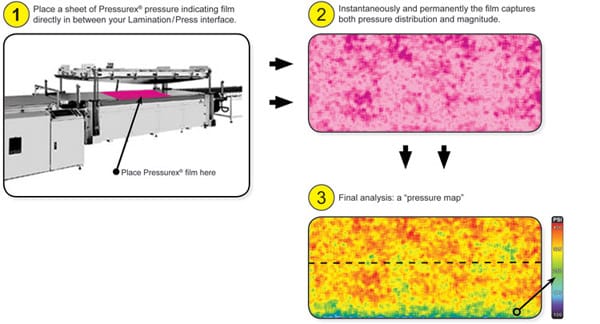

Sensor Products Inc. introduces Pressurex®, a surface pressure indicating film that reveals pressure magnitude and distribution between any two contacting or mating surfaces. In the Photovoltaics industry, the need to reduce peripheral cracks on solar cells has received much attention. Thin film modules of CDTE or CIGS on glass or flexible substrates are particularly susceptible to moisture ingress and require stringent quality control checks. Pressurex® surface pressure indicating film directly fits this bill by providing a low-cost solution for quality control checks during equipment setup, calibration, as well as re-qualification of a solar module production line. Pressurex® assures proper pressure magnitude to cause polymerization and securely bond multiple layers together during EVA and PVB lamination. Negative occurrences such as cracked substrates, squeeze out of materials from the module, and unwanted encapsulant thickness can be reduced by optimizing the quantity of applied pressure. To ensure pressure is evenly distributed over the entire module during the press cycle, Pressurex® pressure indicating film can be inserted into the assembled module layup stack and a “pressure map” control sample can be created and used for process control.

During the frame press stage, Pressurex® sensor film helps verify adequate frame-to-module edge sealing. This unique Mylar-based sensor film reveals surface pressure from 2- 43,000 PSI (0.14-3,000 kg/cm²). Pressurex® film is places at the interface of two contacting surfaces. When these surfaces are compressed together (as a lamination press) they apply a force permanently and irreversibly by virtue of its changing color. Intensity of the color change is proportional to the amount of pressure magnitude by comparing the resultant sensor film’s color to a color calibration reference chart.