Disinfestation of timothy hay bales from Hessian fly (Mayetiola destructor (Say)) puparia using high compression re-baling machines

L.G. Tabil1, A. Ghazanfari1, M. Shaw1, A. Opoku1, W.J. Crerar1 and J. Whistlecraft2

1Department of Agricultural and Bioresource Engineering, University of Saskatchewan, Saskatoon, Saskatchewan S7N 5A9, Canada; and 2Southern Crop Protection and Food Research Center, Agriculture and Agri-Food Canada, London, Ontario N5V 4T3, Canada. *Email: [email protected]

Tabil, L.G., Ghazanfari, A., Shaw, M., Opoku, A., Crerar, W.J. and Whistlecraft, J. 2006. Disinfestation of timothy hay bales from Hessian fly (Mayetiola destructor (Say)) puparia using high compression re-baling machines. Canadian Biosystems Engineering/Le génie des biosystèmes au Canada 48: 3.47 - 3.51. Tests were conducted at a hay baling plant to investigate the efficacy of hay compression on mortality rate of the Hessian fly (Mayetiola destructor (Say)) puparia. Wheat seedlings infested with Hessian fly were placed in cotton organdy cages with two puparia densities of 100 and 50 puparia per cage. The cages were randomly embedded in two types of hay bales (first cut hay and second cut hay) and re-baled at two applied pressure levels of 10.3 and 12.4 MPa. Pressure sensitive films, inserted along with the cages to monitor applied pressures within the bales, indicated that the density of the rebaled hay was approximately 3.4 times the density of the conventional large square bales. Density of the bales also increased with increase in the moisture content of the hay. The mortality of Hessian fly was 100% in all tests compared to overall mortality of field and laboratory controls at 55.8 and 71.2%, respectively.

Des essais ont été complétés à une station de pressage de foin dans le but d’évaluer l’efficacité de la compression du fourrage sur le taux de mortalité des pupes de mouches de Hesse (Mayetiola destructor (Say)). Des semences de blé infestées par la mouche de Hesse ont été placées dans des cages faites d’organdi de coton et ce sous deux différentes concentrations de pupes soit 100 et 50 pupes par cage. Les cages ont été introduites de manière aléatoire dans deux types de balles de foin (première coupe et deuxième coupe) qui ont été compressées à deux pressions différentes soit 10,3 et 12,4 MPa. Des films sensibles à la pression ont été insérés le long des cages pour évaluer les pressions à l’intérieur des balles et ont indiqué que la masse volumique des balles ainsi compressées augmentait de 3,4 fois par rapport à celle de grosses balles carrées conventionnelles. La masse volumique des balles augmentait aussi avec une augmentation de la teneur en eau du foin. Le taux de mortalité de la mouche de Hesse a été de 100% dans tous les tests comparativement à un taux moyen de mortalité au champ et en laboratoire pour les balles contrôles de 55,8 et 71,2% respectivement.

Introduction

Hay production in Canada provides a valuable export crop. Annually, significant amounts of conventionally baled hay are re-baled and exported to other countries such as Japan, Korea, and Taiwan (Alberta Agriculture, Food and Rural Development 2001). Quality of the forage and assurance that the product is free from Hessian fly (Mayetiola destructor (Say)) (Diptera:Cecidomyiidae) infestation are key factors for maintaining or increasing the current export levels.

Hessian fly is a pest of cereal plants such as wheat, barley, and rye across North America (Buntin 1999; Shukle et al. 1990; Whistlecraft and Deakin 1993). The fly lays eggs on the leaves of these plants. Neonate larvae migrate down the leaves to the base of the plant or leaf sheath and feed by sucking nutrients from the plant. Mature larvae can hibernate or estivate for long periods of time within the puparium (flaxseed) (Buntin 1999), until suitable environmental conditions are present for fly emergence. Occasionally, suitable plant hosts for Hessian fly grow as weeds in forage fields and are mixed with hay upon harvesting.

Japan, currently free from the Hessian fly, is a major hay importer from Canada. Because of the Hessian fly quarantine issue, Japan currently requires hay bales to be inspected for host plants before shipment. Japan inspects the imported hay at the port of entry and returns, at the expense of the exporter, any shipments containing host plants.

During the past two decades, many attempts have been made to develop a cost effective method to ensure 100% mortality of Hessian fly puparia in export hay prior to shipment. Yokoyama et al. (1993a, 1993b, 1996) used fumigation and compression for treating the hay bales. They indicated that a combination of fumigation using 2.12 g/m3 aluminum phosphide for seven days followed by compressing the hay at pressures above 7.85 MPa was more effective than fumigation or compression alone. Yokoyama et al. (1993b) reported that 20.6 kPa pressure was sufficient to destroy individual Hessian fly puparium.

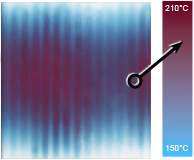

Thermal treatment of hay bales as a means for destruction of Hessian fly puparia has also been investigated (Sokhansanj et al. 1990, 1992, 1993; Opoku et al. 2001). Laboratory studies indicated that exposing hay bales to heated air at 60°C for at least three minutes resulted in total destruction of puparia. The full scale studies on heat treatment of hay bales indicated that, due to variation in bale density, heat penetration within the bales was often incomplete, thus heat treatment was not recommended (Tabil et al. 1999; Opoku et al. 2002, 2003).

With newly developed re-baling machines capable of compressing bales at above 12 MPa, it is reasonable to investigate the mortality of Hessian fly puparia within the bales processed by these machines. Disinfestation of bales by compression is less energy consuming, does not require any additional equipment, and is more environmentally sustainable. Thus, the main objective of this research was to determine the efficacy of new forage compaction equipment in ensuring 100% mortality of Hessian fly puparia.

Materials and Methods

Timothy HayBale compression experiments were conducted at a hay baling plant in Lethbridge, Alberta. Timothy hay (Phleum pratense) used for high compression baling was originally baled using conventional field balers. Two lots of timothy hay, H1 and H2, first cut and second cut, respectively, harvested in 2004, were used for the experiments. The hay of the first lot (H1), grown on irrigated land in the area around Taber, Alberta, was baled on July 4, 2004 and appeared to be greener than that of the second lot (H2) which was grown on irrigated land in the area around Coaldale, Alberta and was baled on October 4, 2004. The moisture content of each lot was determined by placing three approximately 25-g samples from each lot in an air oven and drying them at 103°C for 24 hours (ASAE 2000). Color analysis was also performed on the samples taken from these two lots, using the HunterLab spectrocolorimeter (Hunter Associates Laboratory Inc., Reston, VA). The color was measured in terms of Hunter L, a, and b values. Where L represents lightness to darkness and it is measured on a scale of 0 to +100; a represents greenness to redness on a scale of -50 to +50; and b represents blueness to yellowness on a scale of -50 to +50.

Hessian fly cagesWheat seedlings infested with hibernating Hessian fly puparia were obtained from the Southern Crop Protection and Food Research Center of Agriculture and Agri-Food Canada (AAFCSCPFRC) in London, Ontario. The seedlings, calculated to have an average of 1.95 puparia/seedling and dried at 30°C for 24 hours to remove excess moisture, were placed in 120 × 150 mm cotton organdy cages at two densities of 100 seedlings or 195 puparia (D1) and 50 seedlings or 97.5 puparia (D2) per cage. A total of 253 cages was shipped in controlled environment packages to the test site from which 120 D1 and 120 D2 cages were used for compression tests. The remaining 13 cages were not tested and designated as “field control” (7 D1 and 6 D2). In addition to the shipped cages, 31 cages (14 D1 and 17 D2) were kept in the AAFC-SCPFRC laboratory throughout the testing period and were designated as “lab control”.

Yokoyama et al. (1994a) proposed that all future large scale tests limit the number of insects to 30,000. This suggestion came after the conclusion that an extraordinarily large number of insects were being used in this and their previous studies. Therefore, Yokoyama et al. (1996) reduced the number of puparia to approximately 39,000. Yokoyama et al. (1993a) noted that the infestation levels used in large-scale tests were far in excess of those expected to occur under field conditions. This is because of the fact that host plants are weeds in hay fields, and the occurrence of weeds in export quality hay is low.

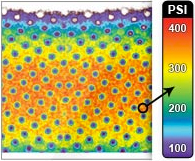

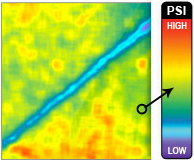

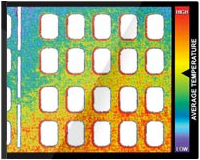

Pressure Sensitive FilmsThe pressure sensitive films (Pressurex® ultra low, Sensor Products Inc., East Hanover, NJ) used in these experiments were able to detect pressures within the range of 200 to 676 kPa. The films were initially opaque and turned into a deep red color when the applied pressure on them exceeded 200 kPa. For the experiments, a film roll was cut to 130 × 130 mm square pieces and they were inserted, along the Hessian fly puparia cages, into the hay prior to compression. The pressurized films were analyzed using the Topaq® pressure analysis software (Sensor Products Inc., East Hanover, NJ) to determine the percent of total film area that experienced pressures below 200 kPa.

Testing ProcedureConventional large square bales (1185 × 1221 × 2436 mm) were transferred to the re-baler system inside the hay baling plant. The bales were untied, sliced into three pieces and conveyed toward a scale unit where the hay was weighed and a predetermined amount was passed to the compression unit of the re-baler system. Before weighing, ten puparia cages, each attached with a pressure film were vertically placed at random locations within the loose hay. For each test, an additional five pressure films were randomly inserted into the hay for further pressure monitoring.

The compression unit of the re-baler system (Hunterwood Technologies Ltd., Cochrane, AB) had twin 305 mm hydraulic plungers with a pressure plate (plunger face) of 0.44 m2 (1.1 m × 0.4 m). The unit operated at a maximum hydraulic line pressure of 37.0 MPa and was capable of exerting a pressure of up to 12.5 MPa on the bales. The loose hay of conventional bales was compacted at two test pressure levels of 10.3 (P1) and 12.4 MPa (P2). Once a desired pressure level was exerted on the hay, it was maintained for 2 s before the newly formed bale was released for strapping. Considering the two levels of pressures, two lots of hay, two densities of Hessian fly cages, and three replicates of each test, a total of 24 bales was made.

Following re-baling, the mass and physical dimensions of each compressed bale were measured. After 30 min, the straps of the bales were cut and the location of the films and the puparia cages were recorded. The films were collected and analyzed for the applied pressure on their surfaces. The puparia cages were returned to the AAFC-SCPFRC where they were placed into individual Petri dishes, moistened, and incubated at a temperature of 18 ± 1oC and relative humidity of 70 ± 5% with 16 hours light and 8 hours darkness, daily. The percentage of fly emergence from the cages was determined after 75 days of incubation.

Results and Discussion

The results of color analysis on H1 and H2 hay are given in Table 1. The lower L value for the H2 hay is an indication of the existence of brown leaves and the lower value of a indicates that the H2 hay was not as green as the H1 hay. Visual inspection also revealed that H1 had greener color while H2 had a significant amount of brown leaves, indicating the higher quality of the first lot of hay.

Table 1. Results of Hunter Lab color analysis on two timothy hay lots.

Table 2. Physical characteristics of conventional and compressed timothy hay bales.

A comparison of physical characteristics of typical conventional and re-baled hays is given in Table 2. The moisture determination indicated that H1 hay had an average moisture content of 9.4% w.b. while H2 hay had an average moisture content of 15.7% w.b. The density of the compact bales is on average 3.4 times the conventional bales which shows a considerable amount of reduction in porosity of the bales after re-baling. In general, the density of the bales increased with both the increase in moisture content and the applied pressure. Similar results have been reported by Ghazanfari et al. (2005) during laboratory studies on hay compression. The table shows that the density for H2 hay is lower when compressed at higher pressure. This is actually due to the difference between the initial weights of the bales due to variation in initial scaling.

Figure 1 shows a typical pressure profile of the plunger faceplate during hay compression testing at 10.3 and 12.4 MPa. The figure shows that the faceplate pressure rose quickly during compression and the pressure was maintained at the desired pressure for a minimum of 2 s. The pressure then decreased sharply after the plunger was released. The figure also shows that the patterns of pressure increase are slightly different for the two baling pressures. In low pressure baling (10.3 MPa), the pressure increased gradually while in high pressure baling the pressure increased more sharply. The rapid increase in pressure for the 12.4 MPa baling indicates that at this pressure, baling is done at a higher speed. Analysis of the curves reveals that bale compression at the higher pressure takes place approximately 1.4 times faster than the low pressure baling. During the initial stage of 12.4 MPa baling, an instantaneous increase in pressure from 0.0 to approximately 1.4 MPa is observed which is followed by a slight decrease and then a gradual increase to its peak value. The initial increase is due to impact loading on the plunger faceplate when it collides with the hay at a high speed. This pattern was not observed on low pressure baling. No definite trend difference was observed in pressure increase curves between the bales of the two lots of hay.

Fig. 1. Typical pressure profile on the bales compressed at two faceplate pressures.

Table 3 highlights the experiment layout and the pressure analysis results for all the films. The table indicates that a small percent of the film area did not experience pressures above the lower sensitivity limit (200 kPa). However, the percentage of total film area below the lower sensitivity limit was very small ( # 0.02%) and it is suspected that this was most likely due to film damage such as creasing and folding. These blemishes to the film introduce minor errors during scanning of the films. A close survey of the scanned images indicated that the reflection and glare from the scanner light appear in contoured areas of the damaged film which are converted to smaller pressure values than have actually been experienced by the film. Visual inspection of the films also indicated that the films which have experienced the higher pressure were also more physically damaged.

Table 3 also shows that all tests conducted were successful in ensuring 100% mortality of Hessian fly puparia. Field controls comprising of D2 and D1 cages had a fly emergence of 46.15 and 42.20% of the total number of expected flies per cage, respectively. Although these cages were not compressed, prepackaging drying and desiccation during transportation and storage obviously had some effect on the mortality of the Hessian fly. The AAFC-SCPFRC laboratory controls showed an emergence of 32.9 and 24.7% of the total number of expected flies for the D2 and D1 cages, respectively. The only difference between the field control and the lab control was that the latter was dried and stored two weeks longer than the field control. This storage time may have further contributed to the reduced emergence of Hessian fly puparia as was observed by Yokoyama et al. (1993a).

Yokoyama et al. (1993a, 1993b) also reported low survival rates for field and laboratory controls. They noted that although the insects were maintained under moist conditions, the high mortalities were most likely due to dessication. This demonstrates the high sensitivity of the Hessian fly, and that even under optimum conditions, low survival rates are experienced. Furthermore, Yokoyama et al. (1994b) discovered that Hessian fly puparia were not able to survive field drying alone, or in combination with any other hay harvesting practise (windrowing, baling, curing, or compression).

Table 3. Experimental layout, results of pressure film analysis, and 75-day emergence of Hessian fly.

Summary and Conclusions

Pressure sensitive film attached to each cage of wheat seedlings infested with Hessian fly were placed in timothy hay bales and re-baled by a commercial hay re-baler system at two pressures, 10.3 and 12.4 MPa. The puparia, packed in cotton organdy cages at two wheat seedling densities of 100 (estimated 195 puparia) and 50 seedlings (estimated 97.5 puparia) per cage, were placed in hay from two separate lots, first cut and second cut. From the analysis of the compression tests and observations on the survival rates of Hessian fly puparia, the following conclusions can be made:

- The density of the bales increased with increases in baling pressure and moisture content of the hay.

- Neither the lot of hay nor the density of infested seedlings had any affect on the efficacy of the forage compactor to ensure 100% mortality.

- The described compression procedure successfully ensured 100% mortality of Hessian fly puparia at both faceplate pressures of 10.3 and 12.4 MPa.

Acknowledgement

Acknowledged for their financial support are the Natural Science and Engineering Research Council (NSERC) and Saskatchewan Agriculture, Food and Rural Revitalization through the Agriculture Development Fund. The authors thank Green Prairie International Inc., Lethbridge, Alberta for the facilities, funding, materials, and expertise. Also acknowledged are Hunterwood Technologies Ltd., Cochrane, Alberta for the technical support, the Canadian Hay Association for logistic support, and Richard Muth of AAFC-SCPFRC for technical support.

References

- Alberta Agriculture, Food and Rural Development. 2001. Timothy hay for export markets. Ag-Ventures Agdex 127/830-1. http://www1.agric.gov.ab.ca/$department/dept docs.nsf/all/agdex4150/$file/127_830-1.pdf?OpenElement (2005/12/07).

- ASAE. 2000. ASAE S358.2 DEC93-Moisture measurementforages. In ASAE Standards 2000, 565. St. Joseph, MI: ASABE.

- Buntin, G.D. 1999. Hessian fly (Diptera:Cecidomyiidae) injury and loss of winter wheat grain yield and quality. Journal of Economic Entomology 92: 1190-1197.

- Ghazanfari, A., A. Opoku and L.G. Tabil. 2005. Characterization of highly compressed timothy hay (Phleum pratense) at different levels of moisture content. CSAESCGR Paper No. 05-079. Winnipeg, MB: CSBE-SCGAB.

- Opoku, A., S. Sokhansanj, W.J. Crerar, G.J. Schoenau and H.C. Wood. 2001. Heat penetration into small rectangular alfalfa/bromegrass bales for insect disinfestation. Canadian Biosystems Engineering 43: 3.31-3.38.

- Opoku, A., S. Sokhansanj, W.J. Crerar, L.G. Tabil and J.W. Whistlecraft. 2002. Disinfestation of Hessian fly puparia in small rectangular hay bales using a laboratory heat treatment unit. Canadian Biosystems Engineering 44: 3.27-3.33.

- Opoku, A., L.G. Tabil, W.J. Crerar, J.W. Whistlecraft and S. Sokhansanj. 2003. Investigating into the thermal kill of Hessian fly puparia embedded in timothy hay bales. CSAESCGR Paper No. 03-340. Winnipeg, MB: CSBE-SCGAB.

- Shukle, R.H., P.B. Grover, Jr. and J.E. Foster. 1990. Feeding of Hessian fly (Diptera:Cecidomyiidae) larvae on resistant and susceptible wheat. Environmental Entomology 19: 494-500.

- Sokhansanj, S., H.C. Wood and V.S. Venkatesan. 1990. Simulation of thermal disinfestations of hay in rotary drum dryers. Transactions of the ASAE 33(5):1647-1651.

- Sokhansanj, S., V.S. Venkatesan, H.C. Wood, J.F. Doane and D.T. Spurr. 1992. Thermal kill of wheat midge and Hessian fly. Postharvest Biology and Technology 2: 65-71.

- Sokhansanj, S., H.C. Wood, J.W. Whistlecraft and G.A. Koivisto. 1993. Thermal disinfestations of hay to eliminate possible contamination with Hessian fly [Mayetiola destructor (Say)]. Postharvest Biology and Technology 3: 165-172.

- Tabil, L.G., M.V. Eliason, J. Whistlecraft and P. Adams. 1999. Field trials leading to the development of a heat treatment protocol for compressed hay bales. ASAE Paper No. 99- 1022. St. Joseph, MI: ASABE.

- Whistlecraft, J.W. and R.J. Deakin. 1993. Hessian fly (Diptera:Cecidomyiidae) biology in southern Ontario and mass rearing using controlled environment rooms. Proceedings of the Entomological Society of Ontario 123: 123-131.

- Yokoyama, V.Y., J.H. Hatchett and G.T. Miller. 1993a. Hessian fly (Diptera: Cecidomyiidae) control by hydrogen phosphide fumigation and compression of hay for export to Japan. Journal of Economic Entomology 86(1): 76-85.

- Yokoyama, V.Y., J.H. Hatchett and G.T. Miller. 1993b. Hessian fly (Diptera: Cecidomyiidae) control by compression of hay for export to Japan. Journal of Economic Entomology 86(3): 803-808.

- Yokoyama, V.Y., J.H. Hatchett, G.T. Miller and P.L. Hartsell. 1994a. Hydrogen phosphide residues and efficacy to control Hessian fly (Diptera: Cecidomyiidae) in compressed hay for export to Japan. Journal of Economic Entomology 87(5): 1272-1277.

- Yokoyama, V.Y., J.H. Hatchett and G.T. Miller. 1994b. Hessian fly (Diptera: Cecidomyiidae) mortality related to moisture, season, temperature, and harvesting practices for compressed and fumigated hay exported to Japan. Journal of Economic Entomology 87(5): 1266-1271.

- Yokoyama, V.Y., G.T. Miller, P.L. Hartsell and J.H. Hatchett. 1996. Complete mortality of Hessian fly (Diptera: Cecidomyiidae) puparia in two large-scale tests to confirm the efficacy of a multiple quarantine treatment for compressed hay exported to Japan. Journal of Economic Entomology 89(3): 705-711.