Article: Plastic News International (UK)

Surface pressure-indicating sensor film ideal for ensuring proper sealing and alignment

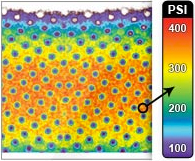

Pressurex® is a thin flexible plastic film that instantly capture; and permanently reveals pressure distribution and magnitude between any two mating or contacting surfaces.

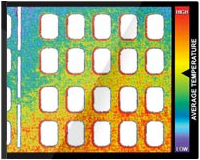

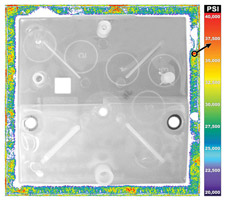

After being clamped up and placed around the parting line of a mould. Pressurex® reveals whether the pressure is evenly distributed.

"With moulds becoming more complex and being exposed to high pressures, it is superior tool to blurring agents which mouldmakers traditionally use." said John Bozzelli, owner of Injection molding Solutions in tl1e USA, who uses Pressurex to demonstrate good or bad parting line mating, and open or closed vents in his consulting and training services.

Pressurex® reveals pressure from 0.14 - 3,000 kg/cm² and is available in eight different pressure ranges with medium and high pressure being the most commonly used for injection molding applications.

When placed between two contacting surfaces. the film instantaneously and permanently changes colour proportionally to the actual pressure applied. Precise pressure magnitude is easily determined by comparing the resultant colour intensity to a colour correlation chart, conceptually similar to interpreting Litmus paper. No training or instrumentation is required.

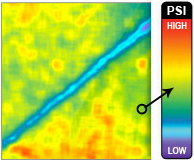

"In injection moulding, Pressurex® confirms that parting lines are mating properly to prevent flash and that the vents are open allowing for proper filling of the mould cavity," said Bozzelli.

"When utilized to check a new or used mould, Pressurex is a great troubleshooting tool for flash, bums and other parting line issues; it can save moulders and mouldmakers thousands of dollars by documenting defects."

Pressurex® has applications in injection moulding, injection-blow. injection-compression, metal injection moulding, gas assist, water assist or any moulding where mating metal surfaces are an issue.

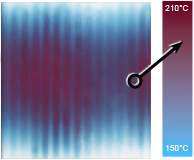

While the temperature parameters of Pressurex® indicate an operating temperature of 5°C to 35°C. which is suitable for testing metal moulds, it has been used at temperature exceeding 150°C for brief periods.

Physically similar in appearance to ordinary papep, Pressurex®, which is 4 or 8 mm thick, conforms to curvaceous surfaces and is available in sheets or rolls that can be cut to size.

It also determines tactile surface pressure distribution in clamping, bolted joints, tooling, comities, lamination presses, nips of rollers, gaskets, heat sealing and score; of other industrial uses.