Pressure Indicating Washer

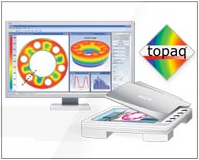

The Tactilus® pressure indicating washer is a revolutionary new means to measure and assess bolted joint tension, design and efficacy. Unlike traditional strain gauged load cells and pressure washers, the Tactilus® pressure sensor is extremely thin, non-invasive and highly economical. The Tactilus® pressure sensor system is a valuable aid in R&D.

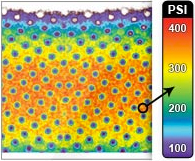

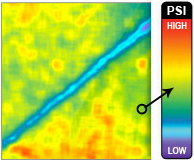

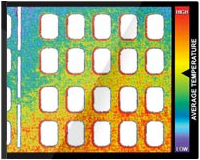

Upon the application of tension the Tactilus® pressure indicating washer reveals precisely how much pressure (tensile load) is being applied at the interface of the bolt and flange surface and how this pressure is circumferentially distributed.

With Tactilus® you only have to invest once in electronics and as your bolt tension monitoring evolves, only the custom tailored sensor element needs to be adapted.

Tactilus® Technology

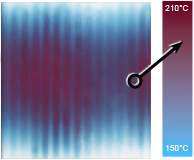

Tactilus® is a tactile surface sensor. Essentially an �electronic skin� that records and interprets pressure distribution and magnitude between any two contacting or mating surfaces and assimilates that data collected into a powerful Windows® based tool kit. Each Tactilus® sensor is carefully assembled to exacting tolerances, individually calibrated and serialized. Tactilus® employs sophisticated mathematical algorithms that intelligently separate signal from noise, and has advanced electronic shielding techniques to maximize environmental immunity to electromagnetic noise, temperature and humidity.

"The Tactilus® pressure indicating washer is the most economical, scientific and user-friendly system for bolt tension evaluation available today." — Jeffrey G. Stark, CEO

| Sensor Specifications | |

| Technology | Resistive |

| Pressure Range | 0 - 250 PSI (0 - 17.5 kg/cm²) |

| Sensing Points | Up to 4 |

| Max Simultaneous channels | Up to 4 |

| Total Sensing Area | Customizable to application |

| Scan Speed | Up to 100 hertz |

| OD | Variable from 0.52 in (1.32 cm) |

| ID | Variable from 0.11 in (0.28 cm) |

| Thickness | 14 mils (0.35 mm) |

| Accuracy | ± 10% |

| Repeatability | ± 2% |

| Hysteresis | ± 5% |

| Non-linearity | ± 1.5% |