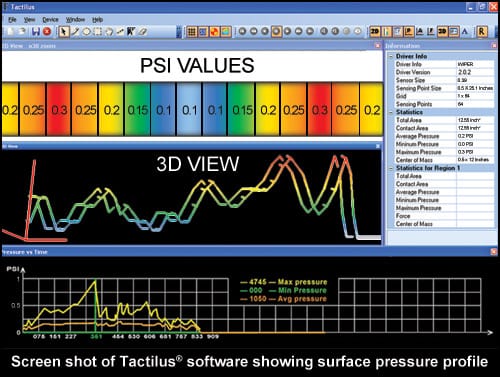

The Tactilus® surface pressure mapping system displays detailed pictures and statistical data of the contact area of the wiper blade and windshield of a car in real-time. Tactilus® uses a powerful windows based tool kit to display images of the contact patch and reveal irregularities in pressure across the entire blade surface. Tests can be performed with Tactilus® in both laboratory and wind tunnel environments.

Tactilus® Technology

Tactilus® is a matrix-based tactile surface sensor. Essentially an “electronic skin” that records and interprets pressure distribution and magnitude between any two contacting or mating surfaces. Each Tactilus® sensor is assembled to exacting tolerances and individually calibrated and serialized. The architectural philosophy of Tactilus® is modular allowing for portability, easy expansion, and simultaneous data collection of up to 4 discrete sensor pads. Tactilus® employs sophisticated mathematical algorithms that intelligently separate signal from noise, and advanced electronic shielding techniques to maximize the sensor’s immunity to noise, temperature and humidity.

“There are many factors that contribute towards blade efficacy such as rubber compound, windshield contour and airflow. Dozens, if not hundreds of design iterations often have to be undertaken to carefully balance these variables. The key proposition of Tactilus® is to minimize or eliminate this iterative process. Everything SPI offers can be custom designed for your specific needs and allow for seamless connectivity with your existing data analysis software.” – Jeffrey G. Stark, CEO

| Sensor Specifications | |

| Technology | Piezoresistive |

| Pressure Range | 0 – 142 PSI (0 – 10 kg/cm²) |

| Grid Size | 1 x 64 |

| Sensing Points | 64 |

| Sensor Dimensions | 0.4” x 32” (1 x 82 cm) |

| Scan Speed | 50 hertz |

| Spatial Resolution | 0.4” (9.35 mm) |

| Thickness | 36.8 mils (0.7 mm) |

| Accuracy | ± 10% |

| Repeatability | ± 98% |