The Innovation

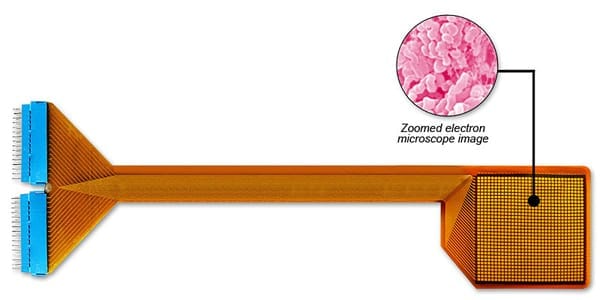

The exciting advancements in Nano-materials have allowed us to introduce the world’s first nano-polymer based tactile surface sensor. With greater temperature resistance, more accuracy, less drift and better repeatability the user now can perform surface mapping analyses with greater confidence than ever before!

What It Does

Tactilus® allow the user to capture and record pressure conditions occurring in between any two contacting or impacting surfaces in real time. The paper-thin Tactilus® sensor is actually placed at the contact interface where it records and assimilates both pressure distribution and pressure magnitude on your Windows® based computer.

Common Applications

- Packaging: nip impression, heat sealing

- Automotive: brake pad, clamping, clutch, fuel cell, gasket/bolted joint, impact study, lamination

- Electronics: heat sink, BGA, connector, lamination, LCD bonding, wafer bonding/polishing

- Aerospace: composite layup, fuel cell, lamination

- Ergonomics: biomechanics, body mapping

Tactilus® Technology

Tactilus® is a matrix-based tactile surface sensor – essentially an “electronic skin” that records and interprets pressure distribution and magnitude between any two contacting or mating surfaces and assimilates the collected data into a powerful Windows® based tool kit. Each Tactilus® sensor is carefully assembled to exacting tolerances and individually calibrated and serialized.

The architectural philosophy of Tactilus® is modular, allowing for portability, easy scalability, and simultaneous data collection from up to four discrete sensor pads Tactilus® employs sophisticated mathematical algorithms that intelligently separate signal from noise, and advanced electronic shielding techniques maximize the sensor’s immunity to noise, temperature and humidity.

Product Benefits

- Low initial investment

- Rapid learning curve ascend (no training required)

- Reusable

| Specifications | |

| Technology | Nano-tubes Composite |

| Surface Pressure Range | *0 – 300 PSI (0 – 21 kg/cm2) |

| Matrix Size | Up to 63 x 55 lines |

| Sensing Points | Up to 3, 465 total |

| Sensing Area Size | Up to 15 x 36 in. (38 x 91 cm) |

| Scan Speed | Up to 800 FPS |

| Temperature Capability | Up to 176°F (80°C) |

| Spatial Resolution | From 0.06 in. (1.6 mm) |

| Thickness | 16 mils (0.4 mm) |

| Accuracy | ± 10% |

| Repeatability | ± 2% |

| Hysteresis | ± 5% |

| Non-linearity | ± 1.5% |

*Sensors larger than 8 in. x 8 in. (20 cm. x 20 cm.) have max pressure capabilities that are lower.

System includes: sensor element, signal conditioning electronics & software.