Function film, Paper, Coated paper, functional paper

Measurement of roll product winding pressure distribution

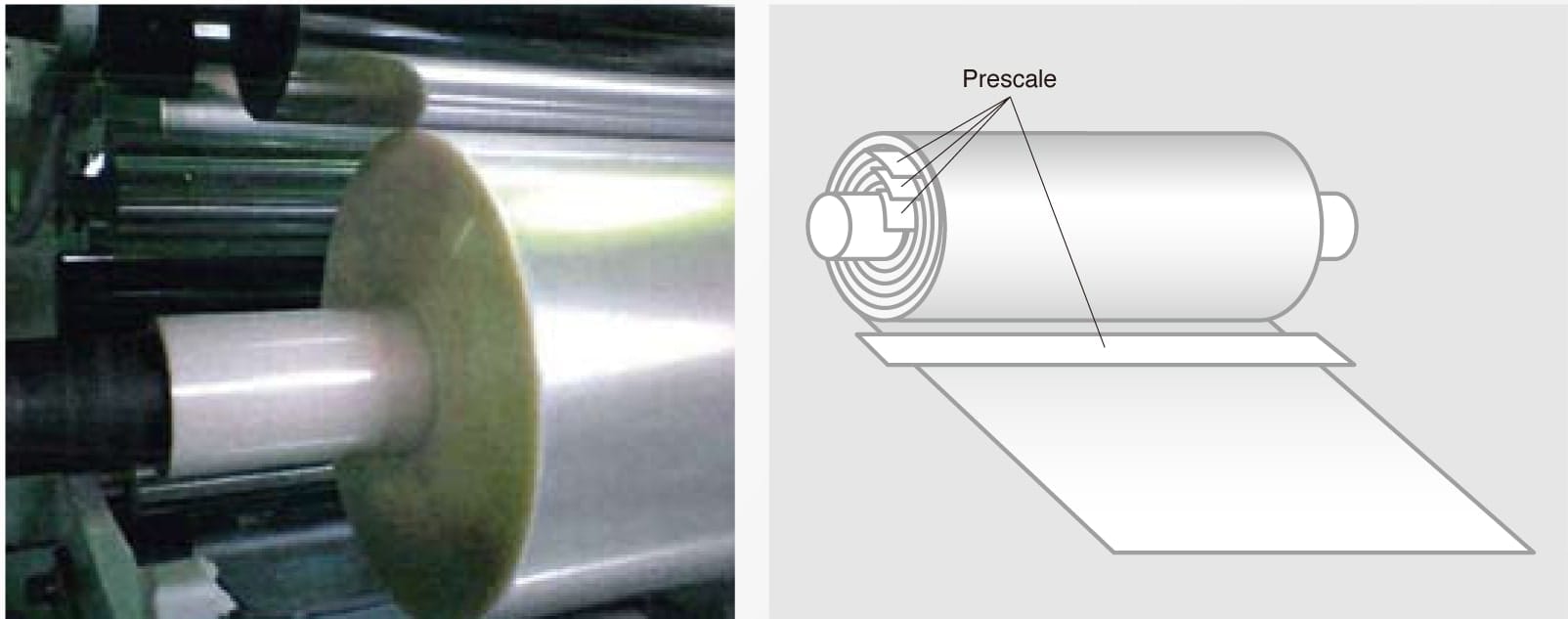

If stress and/or stress distribution during winding is not appropriate, in addition to producing externally visible defects such as star defect and telescoping, quality breakdowns such as indentations and optical distortion defects can occur. Generally, the highest pressure occurs in the core area. Blocking and tapering readily occurs in this area and can result in the loss of several tens to several hundred meters of product. Here, although winding at a low tension level is desirable, winding drift and slack winding can occur if the tension is set too low Rolls are normally wound while tension is increased gradually. However, until recently, no method was available that could determine whether tension conditions are optimal and it was difficult to comprehend and verify the reason behind a problem even if uneven winding, drifting and pressure concentration occurred.

Used product: Prescale (Extreme low pressure 4LW, Ultra low pressure LLLW)

Winding tensions can be adjusted in response to actual changes in winding pressure. When a bias in quality occurs across the width, Prescale can be inserted across the roll width to determine the pressure distribution across the entire width of the roll.

Roll Core Region

Roll Middle Region

Roll Outer Region

Time savings

Less time is required for adjusting tension when changing grades, and for the analysis of quality defects.

Quality improvement

Reduction of material losses by reducing the winding loss length

Without using Prescale

When production grades are changed, winding is normally started at the same tension level that was previously used. If the tension is set too high, the length of winding startup loss increases. If the tension is too low, winding drift or slack winding will occur. As the root cause cannot immediately be identified, the previous procedure would require trial and error analysis and adjustment, and often resulted in the loss of large amounts of material and time.

Using Prescale

When production grades are changed, Prescale cann be used to verify the tension level before winding begins. Based on the results, tension can be adjusted to optimum levels from the second roll. Furthermore, the use of Prescale for verification during analysis allows rapid identification of whether the new process or a previous process is the cause of the problem. This results in time savings and the reduction of material losses.