Pressure Measurement Film

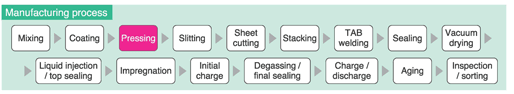

PRESCALE Application Example

Inspection for damage or alignment of rollers used for pressing electrode plates

Measured Object

Rollers for pressing electrode plates of lithium-ion

Measurement

Pressure is applied to a Prescale film inserted between the rollers under normal condition.The color developed in the film is then checked for consistent pressure distribution.This simple procedure verifies the quality or parallel alignment of the rollers

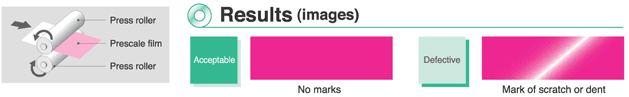

Use example 1

Check for scratches,dents or deformation

Product used

Prescale (Low pressure LW or super low pressure LLW)

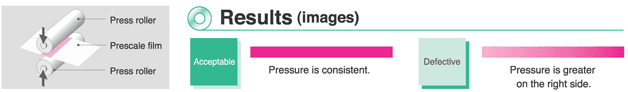

Use example 2

Check for parallel alignment of rollers after gap adjustment

Product used

Prescale (High pressure HS)

Benifits of Prescale

![]() Prescale makes it possible to identify damage on rollers including scratches, dents or deformation.Use of such damaged rollers result in uneven thickness of electrode plates,leading to non-uniform reaction of electro chemicals or other defects.

Prescale makes it possible to identify damage on rollers including scratches, dents or deformation.Use of such damaged rollers result in uneven thickness of electrode plates,leading to non-uniform reaction of electro chemicals or other defects.

![]() Prescale enables roller parallelism adjustment.If the rollers are not parallel, the thickness of the electrode plate varies between the right and left. The plate of uneven thickness cannot be used for either cylindrical or flat batteries when the plate joints are misaligned.

Prescale enables roller parallelism adjustment.If the rollers are not parallel, the thickness of the electrode plate varies between the right and left. The plate of uneven thickness cannot be used for either cylindrical or flat batteries when the plate joints are misaligned.

![]() Optimum tools to perform scheduled roller quality inspections.

Optimum tools to perform scheduled roller quality inspections.