LCDs

Checking uniformity in a polisher.

In the manufacture of LCDs, cullets (glass shavings) may adhere to the panel surface during polishing of the panel edges. When a polarizing plate is mounted on a panel with cullets, air bubbles may form and the yield rate may deteriorate. To prevent this problem, a polisher and washer are used to form a smooth panel. However, since high pressure cannot be applied to the panel surface during polishing, it is very important to maintain sufficient, uniform pressure between the panel and the polishing sheet.

Product used: Prescale (Ultra Low Pressure LLLW)

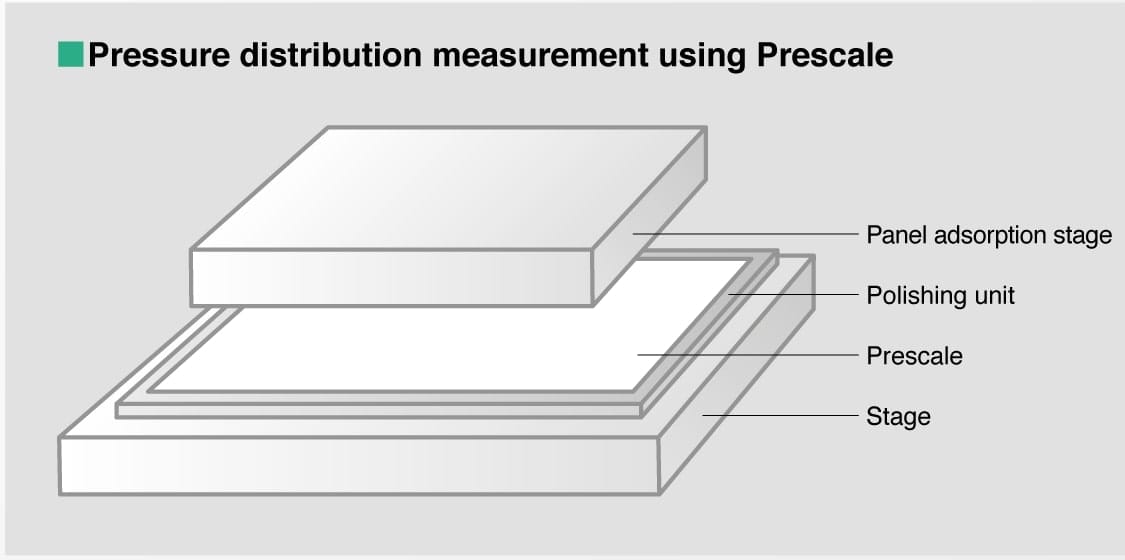

Prescale is placed between the panel adsorption stage and the polishing unit as pressure is applied under normal conditions. The Prescale film is then removed and the color is evaluated to determine process performance. It is easy to evaluate it the panel adsorption stage and polishing unit are in balance.

[Defective]

Pressure is unevenly applied.

[Acceptable]

Pressure balance is even, providing a good result.

Quality loss prevention

Quality problems are easily detectable and output is improved.

Time loss prevention

Pressure uniformity can be quickly checked during design and maintenance.

Without using Prescale

When Prescale is not used in the polishing stage, the resulting defects contribute to increased material and time loss and subsequent process waster. In addition, defects in the polishing process are typically evaluated using visual methods. Adjustments can only be made after repeated trial and error. This process results in the loss of panel materials and increases design adjustment time.

Using Prescale

Pressure distributions are validated during actual use conditions. By checking pressure uniformity in advance, quality improvements and design adjustment time reductions can be achieved.