Packaging for food, pharmaceutical products and other applications.

Understanding and adjusting of optimal conditions for heat sealing

Poor seals include “imperfect seals that are not bonded” and “false seals that appear to be bonded.” False seals are especially a problem because they cannot be indentified visually, and inspection of all items is not possible. Currently, temperature, pressure, time and other parameters are adjusted. If the seal passes later evaluation using the peel strength test (JIS ZO238), it is accepted. Althought instruments exist for measuring temperature and time, there is not yet an instrument for measuring pressure; therefore, trial-and-error is the only method.

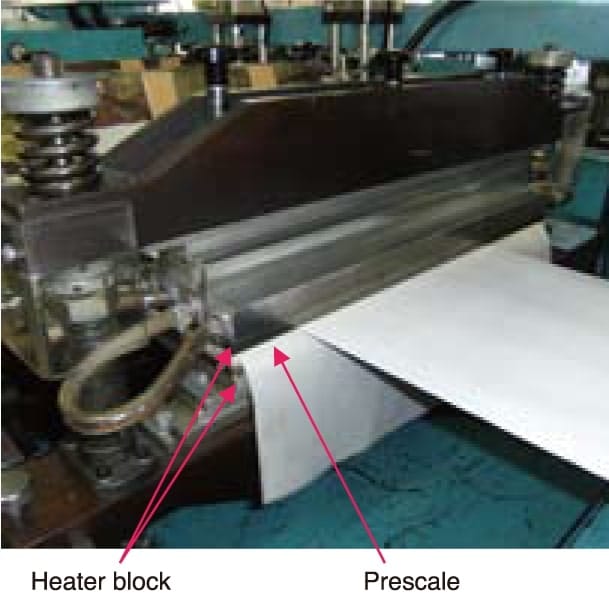

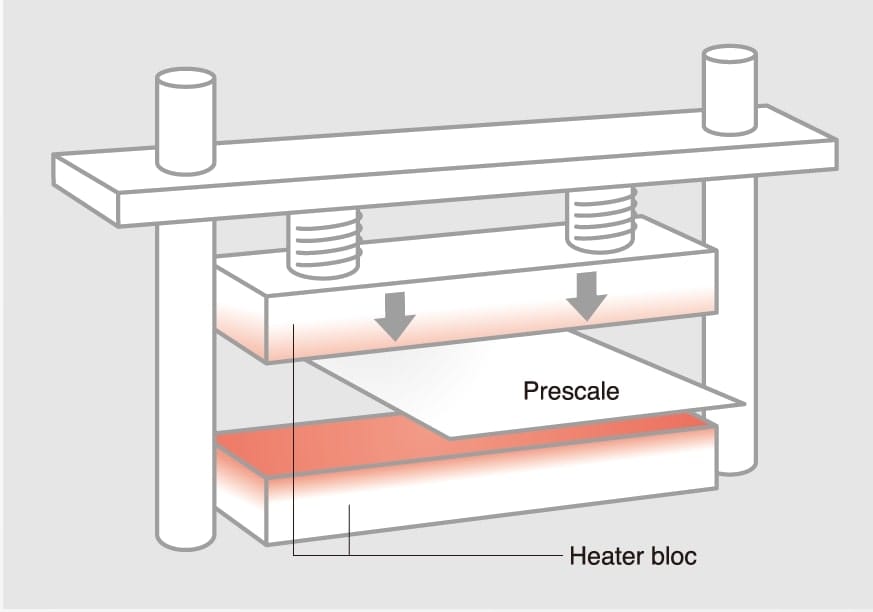

Used product: Prescale (Super Low Pressure LLW )

Pressing Prescale (Super Low Pressure LLW) between heater blocks

Pressure values and pressure distribution are measured with the actual pressure applied. Whether the heater blocks are horizontally parallel and pressure is optimally adjusted can be determined. Prescale can be used to obtain conditions and to make rapid adjustment possible when changing the product type or during maintenance of the heat seal section.

Poor

Quality problems are easily detectable and output yields is improved.

Poor

Quality problems are easily detectable and output yields is improved.

Time savings

Assuming one product change per unit per day, 30 minutes can be saved.

Material savings

Minor (Losses for equipment setting tests, etc., can be reduced).

Quality improvement

Equipment can be set without relying on the instincts of the workers.

Without using Prescale

Strenth of adhesion is measured while changing the temperature, true and pressure parameters. Trail-and-error measurements are repeated until adequate adhesive strenght is achieved. when the pressure remains uneven, heating (e.g., high temperature, long time ) is used to force the sealing. –> false adhesion is likely to occur.

Using Prescale

Prescale can be used to optimize the pressure level and pressure balance. Temperature and time can be optimized as parameters. Adhesive strenght evaluation (JIS Z0238) is used for final confirmation.