Displays, printed boards, lead frames, food and pharmaceutical products, packaging materials

Assessment of rubber roll mounting quality

Lamination film is passed between nip rolls made from rubber mounted on steel cores in the lamination process. If the adhesion of the rubber to the stell core of the lamination nip roll is poor or if the rubber is damaged, lamination defects occur. This poor adhesion and damage cannot be detected by external examination of the roll.

Also, variations in the thickness of the rubber or core alignment, uneven hardness, etc. can result in non-uniform nip pressure distribution that results in lamination thickness variation and poor transport, including drifting.

Also, variations in the thickness of the rubber or core alignment, uneven hardness, etc. can result in non-uniform nip pressure distribution that results in lamination thickness variation and poor transport, including drifting.

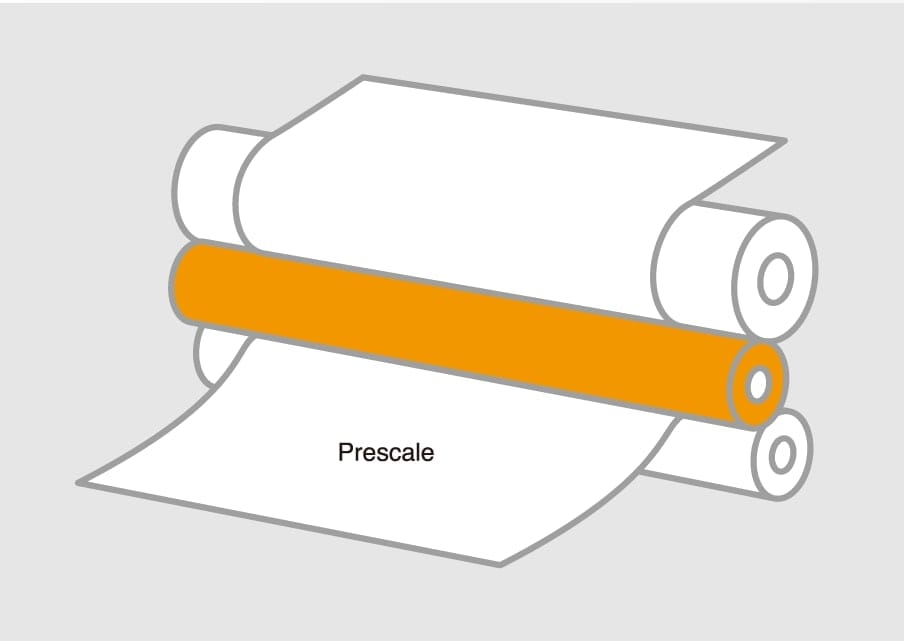

Used product: Prescale (Super Low Pressure LLW)

The lamination nip rolls are installed in the nip unit and Prescale (LLW) is inserted between the nip rolls. The actual operating pressure is applied and the roll is rotated once.

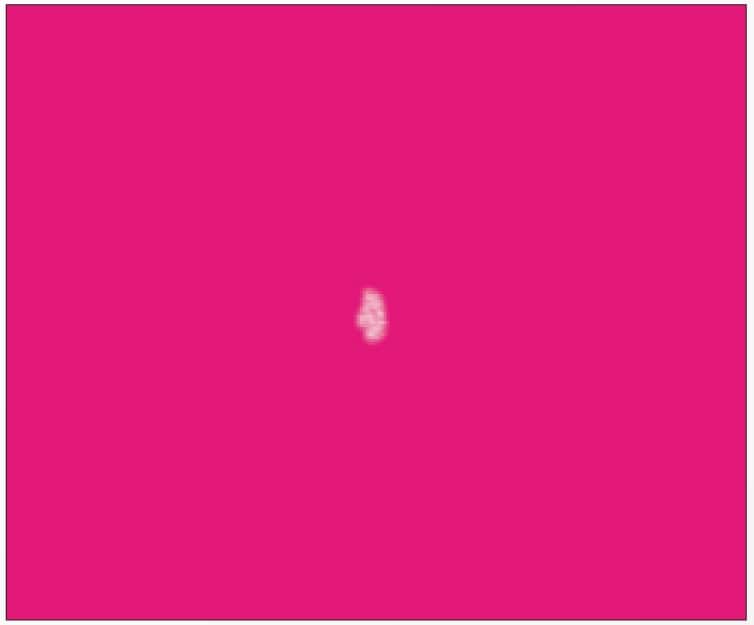

If uniform color is visually confirmed, the roll can be accepted.

If uniform color is visually confirmed, the roll can be accepted.

Although variations in thickness, core alignment, and distortion of the roll can be measured optically, the use of Prescale is the only simple method for evaluating poor adhesion of the rubber and steel core of the lamination nip rolls, minute damage to the rubber surface and variation in the hardness of the rubber.

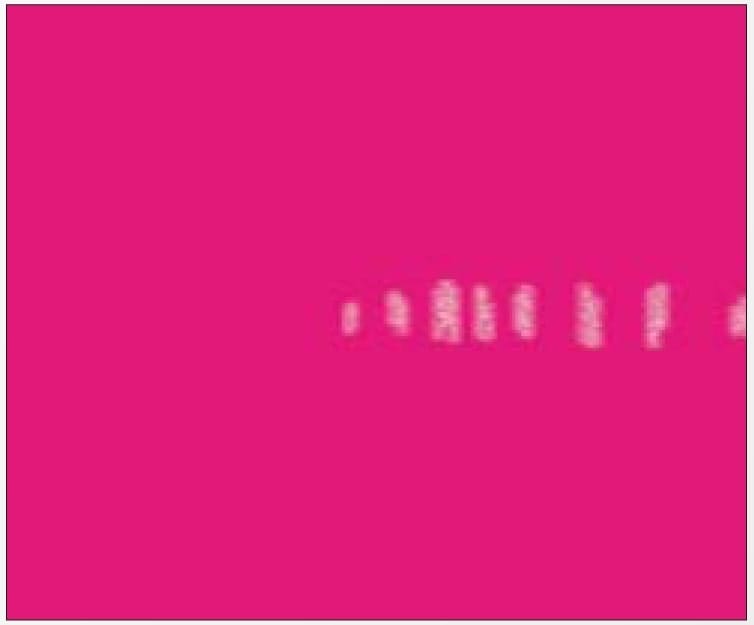

Poor

Surface damage

Poor

Poor adhesion of the steel core and rubber

Time savings

For roll exchange, etc., approximately half a day can be saved.

Material savings

The occurence of material loss (loss of glass substrates for LCDs,etc.) can be prevented when defects occur.

Quality improvement

Defects can be prevented and yield can be increased.

Without using Prescale

If rolls are installed on production quipment without evaluation using Prescale and there are problems, large losses of time, material and quality will occur.

Using Prescale

Even if there is problem with a roll, products are not affected. Rolls can be improved by polishing, etc. until adequate quality is achieved. Also, in the worst case, the rubber can be replaced.