Touch panels and LCDs

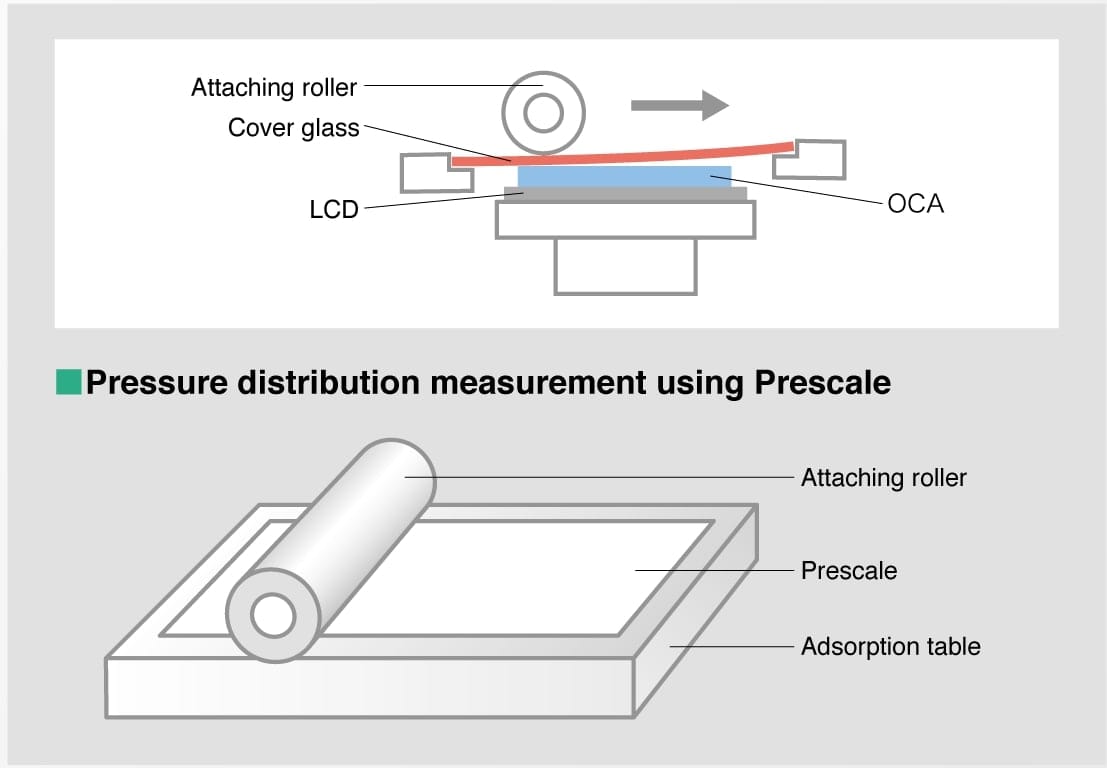

Checking roller pressure uniformity when attaching the cover glass to touch panels or LCDs.

The diversification of products for touch panels (e.g., smart phones, tablet PCs, portable games, and car navigation systems) has increased the complexity of attaching materials such as hard cover glass onto panels. Since precision attachment is required between these hard materials, uneven pressure during the attachment process can cause air bubbles and other problems.

Product used: Prescale (Ultra Super Low Pressure LLLW)

Prescale is placed between the adsorption table, touch panel or LCD and the attachment roller, then pressure is applied under normal conditions. The Prescale film is then removed and the color is evaluated to determine process performance. It is easy to evaluate if the adsorption table and attaching roller are in balance.

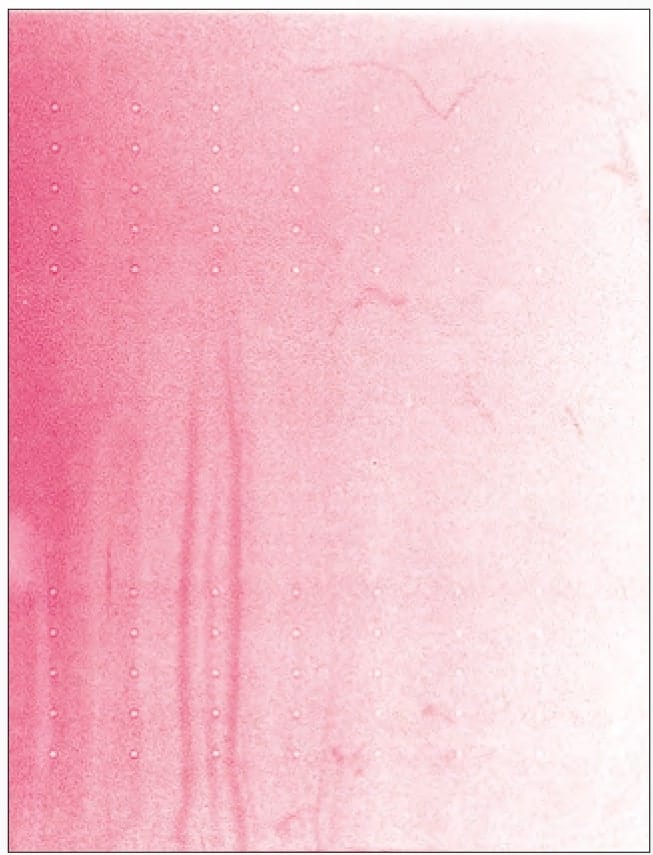

[Defective]

Pressure is unevenly applied.

[Acceptable]

Pressure balance is even, providing a good result.

Quality loss prevention

Quality problems are easily detectable and output yields is improved.

Time loss prevention

Pressure uniformity can be quickly checked during design and maintenance.

Without using Prescale

When Prescale is not used, attaching results must be evaluated. Adjustments require repeated trial and error to resolve defects. This process will result in material loss and increase design adjustment time.

Using Prescale

Pressure distributions are validated during actual use conditions. By checking pressure uniformity in advance, quality improvements and design adjustment time reductions can be achieved.