Printed Circuit Board (PCB), lead frames, liquid crystal glass substrate circuit formation

Checking adhesive pressure of dry film resist (DFR) lamination

When laminating dry film resist onto print substrates or lead frames, bubbles and wrinkles can be formed if the base material/dry film resist/ lamination roll is not set up in balance or if the pressure is not adjusted to be uniform. Also, if the pressure is not set to the optimum value, bubbles can be enter surface irregularties and adhesion defects can result. Although pressure uniformity is vital to process stabilization there has been no method available to measure it.

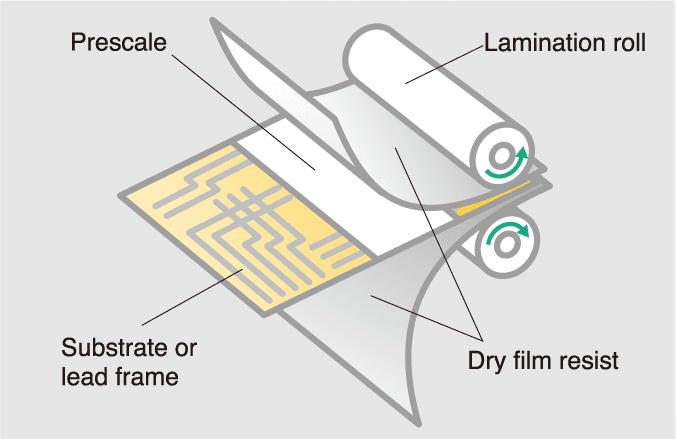

Used product: Prescale (Ultra low pressure LLLW, Super low pressure LLW)

1

Apply the Prescale (LLLW, LLW) to the print substrate or lead frame. Then, convey the Prescale along with the substrate or lead frame.

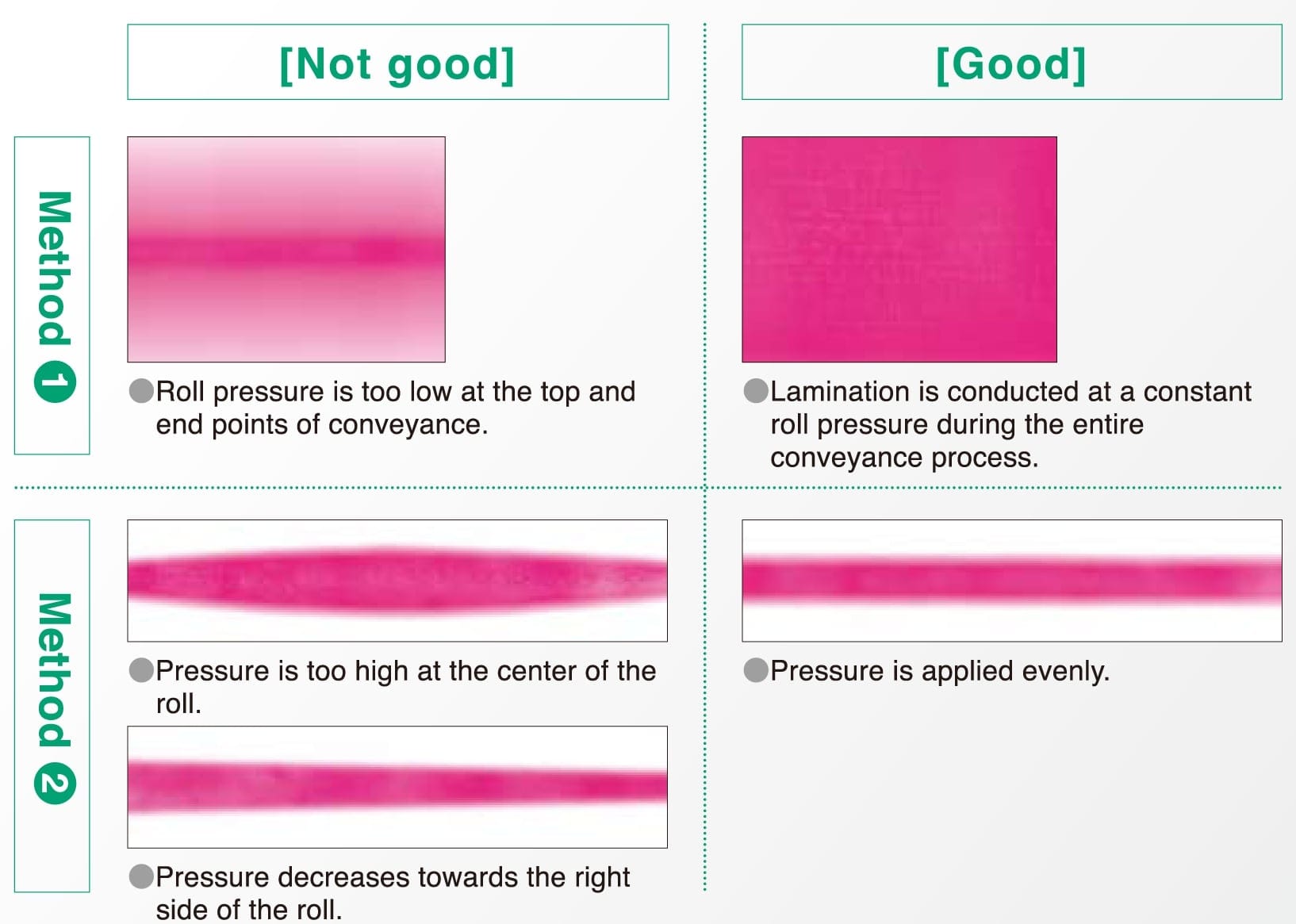

Prescale is passed between the calender rolls. The uniformity of the resulting Prescale color density is used ot evaluate whether the pressure balance is appropriate.

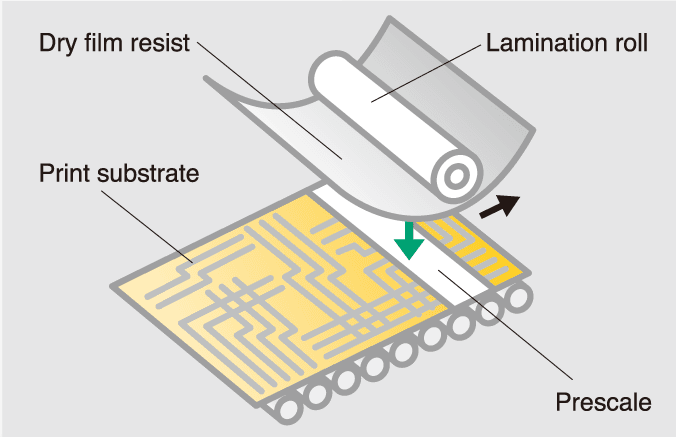

2

Apply the Prescale (LLW, LLW) to the print substrate or lead frame. Then adjust the lamination roll from its loose state to the prescribed pressure and conduct the measurement.

According to the coloring of the Prescale; check whether or not the pressure of the lamination roll is applied uniformly and at the prescribed value.

Time savings

Without Prescale, schedules may be affected for several days if you need to call out a technician from the manufacturer for maintenance.

Material savings

Without Prescale, material losses occur due to the need to use trial-and-error processes.

Quality improvement

Without using Prescale, quality problems can occur due to inspection lapses.

Without using Prescale

When the cause of abnormalities such as wrinkles is not understood, it is necessary to perfor repeated corrections by trail and error, resutling in substantial waste.

Durning maintenance to call out technicians from the manufacturer, resulting in substantial time losses and service costs (e.g., schedule adjustments and travel expenses).

Durning maintenance to call out technicians from the manufacturer, resulting in substantial time losses and service costs (e.g., schedule adjustments and travel expenses).

Using Prescale

It is possible to check that the lamination roll pressure is applied uniformly at the prescribed value.

Also, abnormalities and maintenance can be handled onsite of calling out a techinician from the manufacturer, resulting in cost and time savings.

Also, abnormalities and maintenance can be handled onsite of calling out a techinician from the manufacturer, resulting in cost and time savings.