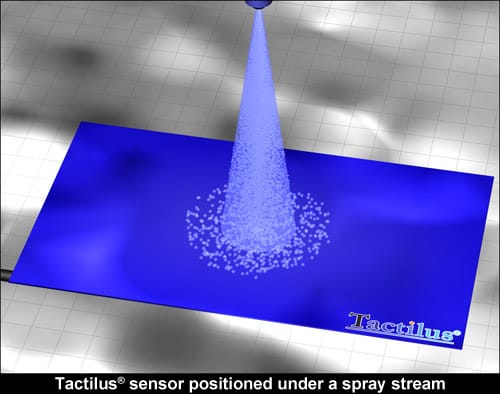

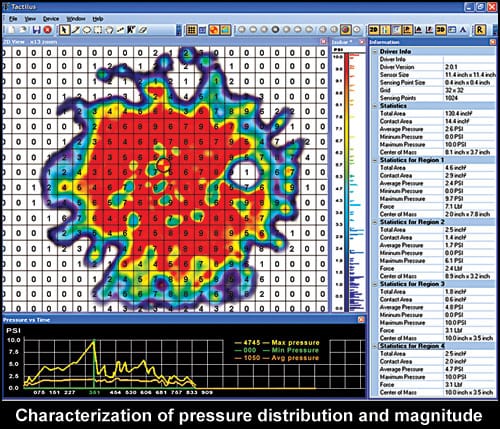

Our Tactilus® spray sensor reveals contact impact pressure distribution and magnitude across the entire surface area of your spray surface. Now for the fist time you can verify FEA and CFD analyses with data gathered directly from your contact surface.

The Tactilus® sensor sits right at the contact surface where your spray stream impacts. Tactilus® is real time and fast -30 hertz, for reliable observation of the spray pattern as it varies over time.

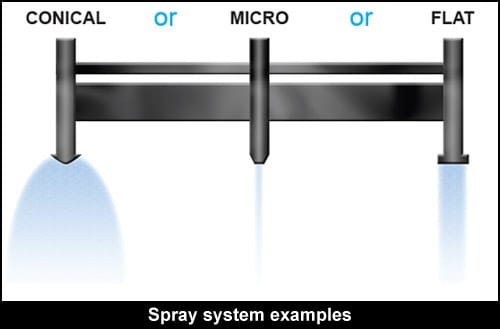

Through the interpretation of pressure data obtained from the Tactilus® system, a designer, manufacturer or researcher of spray nozzles and spray charactarization may identify whether pressures and surface coverages are as desired.

Download

White Papers

Tactilus® Technology

Tactilus® is a matrix-based tactile surface sensor. Essentially an “electronic skin” that records and interprets pressure distribution and magnitude between any two contacting or mating surfaces and assimilates that data collected into a powerful Windows® based tool kit. Each Tactilus® sensor is carefully assembled to exacting tolerances and individually calibrated and serialized.

The architectural philosophy of Tactilus® is modular allowing for portability, easy expansion, and simultaneous data collection of up to 4 discrete sensor pads. Tactilus® employs sophisticated mathematical algorithms that intelligently separate signal from noise, and advanced electronic shielding techniques to maximize the sensor’s resistance to noise, temperature and humidity.

| Sensor Specifications | |

| Technology | Piezoresistive |

| Pressure Range | 0 – 100 PSI (0 – 7 kg/cm²) |

| Grid Size | 32 x 32 |

| Sensing Points | 1,024 |

| Max Sensing Area | 19 x 19 in (48.3 x 48.3 cm) |

| Scan Speed | Up to 30 hertz |

| Spatial Resolution | Custom from 0.4 in (9 mm) |

| Thickness | 25 mils (0.6 mm) |

| Accuracy | ± 10% |

| Repeatability | ± 2% |

| Hysteresis | ± 5% |

| Non-linearity | ± 1.5% |