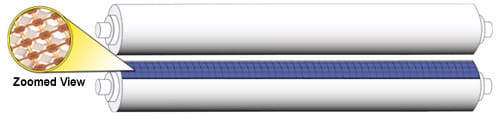

Illustration of a Tactilus® sensor positioned in a PCB lamination nip roller

Wrinkle Containment and Pressure Uniformity Control for Dry Film Resist Lamination

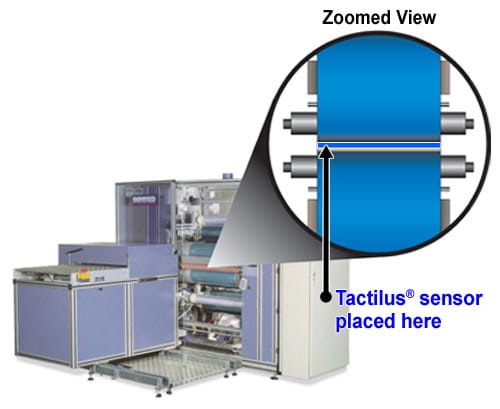

Tactilus® sensor positioned in a PCB lamination nip press

Have you ever needed to evaluate pressure or force between two touching or mating surfaces? Previously, your only alternatives were strain gauges and load cells, that are both time consuming and difficult to interface. Now with the advent of Tactilus®, evaluating surface contact pressure distribution and magnitude is accurate and quick.

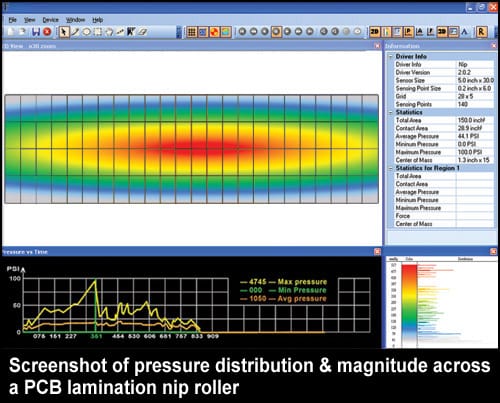

Tactilus® is used to measure nip roller pressure in the lamination process during the manufacture of PCBs. When performing the process of dry film lamination upon a composite structure or photopolymer and polyester film to a metal-clad dielectric there often exists the possibility of the photoresist wrinkling or bubbling. By carefully monitoring both pressure magnitude and distribution within your lamination rollers, with Tactilus®, wrinkling induced defects can be significantly reduced. Over tightened or loose or worn roll chucks can cause roller misalignments and imperfect nips – both of which are the primary contributors to intermittent wrinkling.

Tactilus® Technology

Screenshot of pressure distribution & magnitude across a PCB lamination nip roller

Tactilus® is a matrix based tactile surface sensor. Essentially an “electronic skin” that records and interprets pressure distribution and magnitude between any two contacting or mating surfaces and assimilates that data collected into a powerful, yet user-friendly, Windows® based tool kit. Each Tactilus® sensor is carefully assembled to exacting tolerances and individually calibrated and serialized. The architectural philosophy of Tactilus® is modular allowing for portability, easy expansion, and simultaneous data collection of up to 6 discrete sensor pads. Tactilus® employs sophisticated mathematical algorithms that intelligently separate signal from noise, and advanced electronic shielding techniques to maximize environmental immunity to noise, temperature and humidity. Our proprietary sensor design ensures the most robust sensor in the industry – an investment that will sustain thousands of uses.

| Sensor Specifications | |

| Pressure Range | 0.001 — 200 PSI (0.007 — 14.10 kg/cm²) |

| Sensor Size | Customizable from 1 sq in (2.54 cm²) |

| Spatial Resolution | Customizable from 0.03 inches (0.8 mm) |

| Scan Speed | 100 sensing points per second |

| Accuracy | ± 10% |

| Repeatability | ± 2% |

| Hysteresis | ± 5% |

| Non-Linearity | ±1.5% |