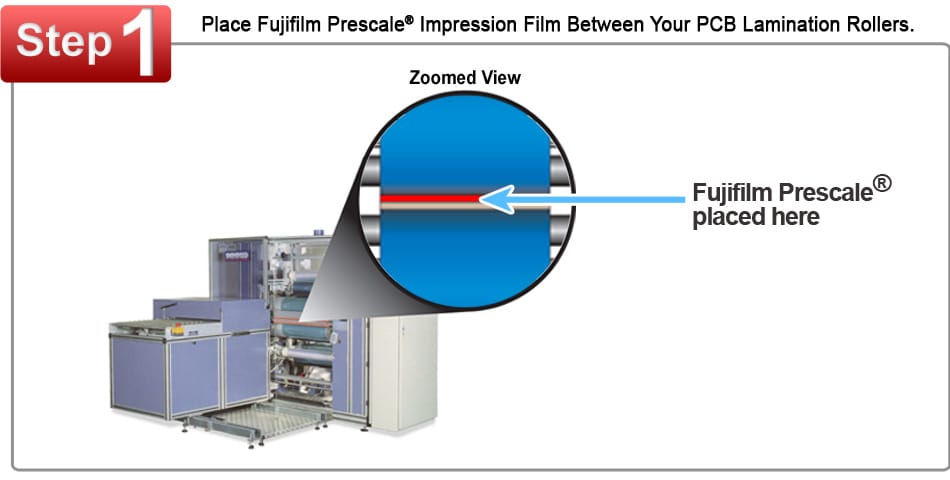

Fujifilm Prescale® Film Placed Between PCB Lamination Rollers

Fujifilm Prescale® is a unique, affordable and easy to use tool that reveals the distribution and magnitude of pressure between your lamination rollers.

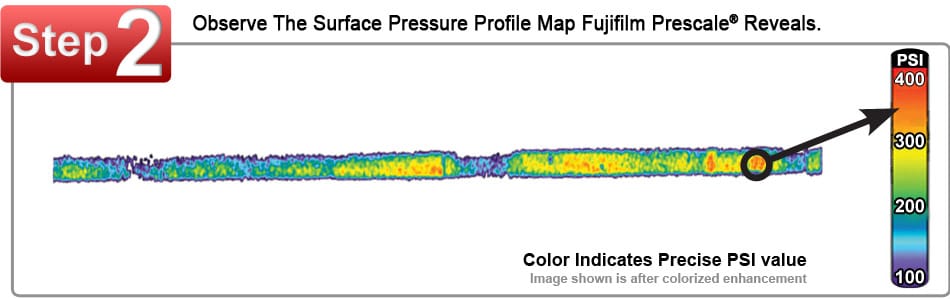

Fujifilm Prescale® is used to measure nip roller pressure in the lamination process during the manufacture of PCBs. When performing the process of dry film lamination upon a composite structure or photopolymer and polyester film to a metal-clad dielectric there often exists the possibility of the photoresist wrinkling or bubbling. By carefully monitoring both pressure magnitude and distribution within your lamination rollers, with pressure indicating films, wrinkling induced defects can be significantly reduced. Over tightened or loose or worn roll chucks can cause roller misalignments and imperfect nips – both of which are the primary contributors to intermittent wrinkling.

When placed between two nip rollers, the film instantaneously and permanently changes color in direct proportion to the actual pressure applied. Philosophically similar to the indication given by Litmus paper. Precise pressure magnitude is then easily determined by comparing the resultant color intensity to a standardized color correlation chart No training or instrumentation is required.

Fujifilm Prescale® is extremely thin (4 to 8 mils) which enables it to conform to curved surfaces. It is ideal for invasive intolerant environments and tight spaces not accessible to conventional electronic transducers.

Have you ever needed to evaluate pressure or force between two touching or mating surfaces? Previously, your only alternatives were strain gauges and load cells, that are both time consuming and difficult to interface. Now with the advent of our disposable one-time use pressure film, Fujifilm Prescale®, evaluating surface contact pressure distribution and magnitude is accurate, quick and highly economical.

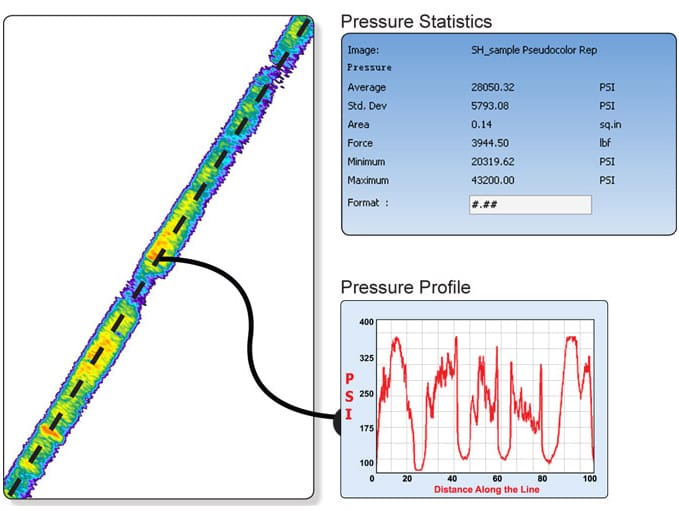

Final Analysis Pressure Map of a PCB Lamination Press Image

| Pressure Film Type | Code | Alternative Code | Pressure Range | Order Now |

| Ultra Extreme Low | 5LW | UXL310 | 0.87 – 7.3 PSI (0.06 – 0.51 kg/cm2) | Order Now |

| Extreme Low | LLLLW / 4LW | XL310 | 7.2 – 28 PSI (0.5 – 2 kg/cm2) | Order Now |

| Ultra Low | LLLW | UL270 | 28 – 85 PSI (2 – 6 kg/cm2) | Order Now |

| Super Low | LLW | SL270 | 70 – 350 PSI (5 – 25 kg/cm2) | Order Now |

| Low | LW | L270 | 350 – 1,400 PSI (25 – 100 kg/cm2) | Order Now |

| Medium | MS | M270 | 1,400 – 7,100 PSI (100 – 500 kg/cm2) | Order Now |

| High | HS | H270 | 7,100 – 18,500 PSI (500 – 1,300 kg/cm2) | Order Now |

| Super High | HHS | SH270 | 18,500 – 43,200 PSI (1,300 – 3,000 kg/cm2) | Order Now |

| Physical Specifications | |

| Operating Temperature | 68°F – 95°F (20°C – 35°C) much higher for brief exposure |

| Humidity Range | 20% to 90% RH |

| Gauge (Thickness) | 4 – 20 mils |

| Spatial Resolution | From 5 – 15 microns |

| Substrate | Polyethylene Terephthalate (PET) |

| Accuracy | ± 10% visual, ± 2% Utilizing optional optical measurement systems |

| Shelf Life | 1 Year |