~Credit to Dr. RM Crowder

Touch and tactile sensor are devices which measures the parameters of a contact between the sensor and an object. This interaction obtained is confined to a small defined region. This contrasts with a force and torque sensor that measures the total forces being applied to an object. In the consideration of tactile and touch sensing, the following definitions are commonly used:

Touch Sensing

This is the detection and measurement of a contact force at a defined point. A touch sensor can also be restricted to binary information, namely touch, and no touch.

Tactile Sensing

This is the detection and measurement of the spatial distribution of forces perpendicular to a predetermined sensory area, and the subsequent interpretation of the spatial information. A tactile-sensing array can be considered to be a coordinated group of touch sensors.

Slip

This is the measurement and detection of the movement of an object relative to the sensor. This can be achieved either by a specially designed slip sensor or by the interpretation of the data from a touch sensor or a tactile array.

Tactile sensors can be used to sense a diverse range of stimulus ranging from detecting the presence or absence of a grasped object to a complete tactile image. A tactile sensor consists of an array of touch sensitive sites, the sites may be capable of measuring more than one property. The contact forces measured by a sensor are able to convey a large amount of information about the state of a grip. Texture, slip, impact and other contact conditions generate force and position signatures, that can be used to identify the state of a manipulation. This information can be determined by examination of the frequency domain, and is fully discussed in the literature.

As there is no comprehensive theory available that defines the sensing requirements for a robotic system, much of the knowledge is drawn from investigation of human sensing, and the analysis of grasping and manipulation. Study of the human sense of touch suggests that creating a gripper incorporating tactile sensing requires a wide range of sensors to fully determine the state of a grip. The detailed specification of a touch sensor will be a function of the actual task as it is required to perform. Currently no general specification of a touch or tactile sensor exists the following can be used as an excellent basis for defining the desirable characteristics of a touch or tactile sensor suitable for the majority of industrial applications:

- A touch sensor should ideally be a single-point contact, through the sensory area can be any size. In practice, an area of 1-2 mm2 is considered a satisfactory compromise between the difficulty of fabricating a sub-miniature sensing element and the coarseness of a large sensing element.

- The sensitivity of the touch sensor is dependent on a number of variables determined by the sensor’s basic physical characteristic. In addition the sensitivity may also be the application, in particular any physical barrier between the sensor and the object. A sensitivity within the range 0.4 to 10N, together with an allowance for accidental mechanical overload, is considered satisfactory for most industrial applications.

- A minimum sensor bandwidth of 100 Hz.

- The sensor‘s characteristics must be stable and repeatable with low hysteresis. A linear response is not absolutely necessary, as information processing techniques can be used to compensate for any moderate non-linearities.

- As the touch sensor will be used in an industrial application, it will need to be robust and protected from environmental damage.

- If a tactile array is being considered, the majority of application can be undertaken by an array 10-20 sensors square, with a spatial resolution of 1-2 mm.

In a dexterous end effector, the forces and relative motions between the grasped object and the fingers need to be controlled. This can be achieved by using a set of sensors capable of determining in real time, the magnitude, location, orientation of the forces at the contact point. This problem has been approached by using miniature force and torque sensors inside the finger tips, to provide a robot with an equivalent to the kinesthetic sense found in humans. The integration of skin like and kinesthetic-like sensing will result in robots being equipped with artificial haptic perceptions.

Touch sensor technology

Many physical principles have been exploited in the development of tactile sensors. As the technologies involved are very diverse, this chapter can only consider the generalities of the technology involved. In most cases, the developments in tactile sensing technologies are application driven. It should be recognised that the operation of a touch or tactile sensor is very dependant on the material of the object being gripped.. The sensors discussed in this chapter are capable of working with rigid objects. However if non-rigid material is being handled problems may arise. Work has shown that conventional sensors can be modified to operate with non-rigid materials.

Mechanically based sensors

The simplest form of touch sensor is one where the applied force is applied to a conventional mechanical micro-switch to form a binary touch sensor. The force required to operate the switch will be determined by the its actuating characteristics and any external constraints. Other approaches are based on a mechanical movement activating a secondary device such as a potentiometer or displacement transducer.

Resistive based sensors

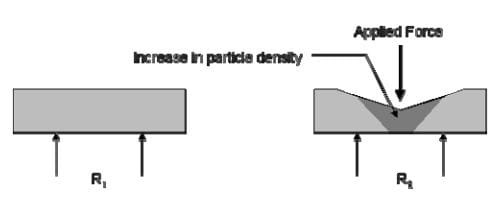

The use of compliant materials that have a defined force-resistance characteristics have received considerable attention in touch and tactile sensor research. The basic principle of this type of sensor is the measurement of the resistance of a conductive elastomer or foam between two points. The majority of the sensors use an elastomer that consists of a carbon doped rubber.

The conductive elastomer or foam based sensor, while relatively simple does suffer from a number of significant disadvantages:

• An

elastomer has a long nonlinear time constant. In addition the time constant of the elastomer, when force is applied, is different from the time constant when the applied force is removed.

• The force-resistance characteristic of elastomer based sensors are highly nonlinear, requiring the use of signal processing algorithms.

• Due to the cyclic application of forces experience by a tactile sensor, the resistive medium within the elastomer will migrates over a period of time. Additionally, the elastomer will become permanently deformed and fatigue leading to permanent deformation of the sensor. This will give the sensor a poor long-term stability and will require replacement after an extended period of use.

Even with the electrical and mechanical disadvantages of conductive elastomers and foams, the majority of industrial analogue touch or tactile sensors that have been based on the principle of resistive sensing. This is due to the simplicity of their design and interface to the robotic system.

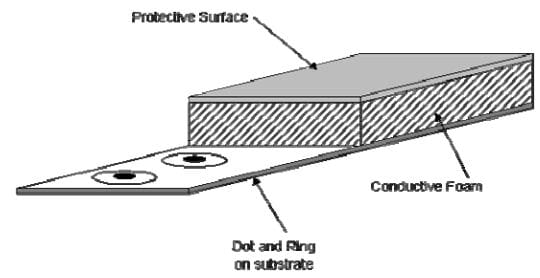

Force sensing resistor

A force sensing resistor is a piezoresistivity conductive polymer, which changes resistance in a predictable manner following application of force to its surface. It is normally supplied as a polymer sheet which has had the sensing film applied by screen printing. The sensing film consists of both electrically conducting and non-conducting particles suspended in matrix. The particle sizes are of the order of fraction of microns, and are formulated to reduce the temperature dependence, improve mechanical properties and increase surface durability. Applying a force to the surface of a the sensing film causes particles to touch the conducting electrodes, changing the resistance of the film. As with all resistive based sensors the force sensitive resistor requires a relatively simple interface and can operate satisfactorily in moderately hostile environments.

Force sensing resistor

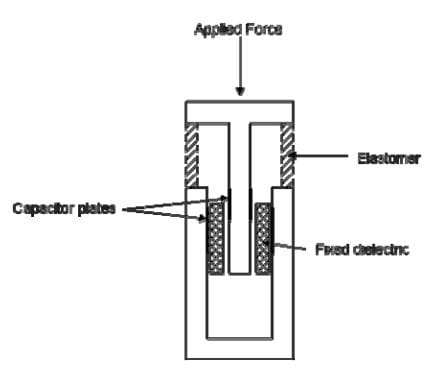

The capacitance between two parallel plates is given by:

A

C= ———

d

where A is the plate area, d the distance between the plates, and e the permittivity of the dielectric medium. A capacitive touch sensor relies on the applied force either changing the distance between the plates or the effective surface area of the capacitor. In such a sensor the two conductive plates of the sensor are separated by a dielectric medium, which is also used as the elastomer to give the sensor its force-to-capacitance characteristics.

To maximize the change in capacitance as force is applied, it is preferable to use a high permittivity, dielectric in a coaxial capacitor design. . In this type of sensor, as the size is reduced to increase the spatial resolution, the sensor‘s absolute capacitance will decrease. With the limitations imposed by the sensitivity of the measurement techniques, and the increasing domination of stray capacitance, there is an effective limit on the resolution of a capacitive array. The figure shows the cross section of the capacitive touch transducer in which the movement of a one set of the capacitors’ plates is used to resolve the displacement and hence applied force. The use of a highly dielectric polymer such as polyvinylidene fluoride maximizes the change capacitance. From an application viewpoint, the coaxial design is better as its capacitance will give a greater increase for an applied force than the parallel plate design

Magnetic based sensor

There are two approaches to the design of touch or tactile sensors based on magnetic transduction. Firstly, the movement of a small magnet by an applied force will cause the flux density at the point of measurement to change. The flux measurement can be made by either a Hall effect or a magnetoresistive device. Second, the core of the transformer or inductor can be manufactured from a magnetoelastic material that will deform under pressure and cause the magnetic coupling between transformer windings, or a coil‘s inductance to change. A magnetoresistive or magnetoelastic material is a material whose magnetic characteristics are modified when the material is subjected to changes in externally applied physical forces. The magnetorestrictive or magnetoelastic sensor has a number of advantages that include high sensitivity and dynamic range, no measurable mechanical hysteresis, a linear response, and physical robustness.

If a very small permanent magnet is held above the detection device by a complaint medium, the change in flux caused by the magnet’s movement due to an applied force can be detected and measured. The field intensity follows an inverse relationship, leading to a nonlinear response, which can be easily linearized by processing. A one-dimensional sensor where a row of twenty hall effect devices placed opposite a magnet has been constructed. A tactile sensor using magnetoelastic material has been developed, where the material was bonded to a substrate, and then used as a core for an inductor. As the core is stressed, the material‘s susceptibility changed, which is measured as a change in the coil‘s inductance.

Optical Sensors

The rapid expansion of optical technology in recent years has led to the development of a wide range of tactile sensors. The operating principles of optical-based sensors are well known and fall into two classes:

• Intrinsic, where the optical phase, intensity, or polarization of transmitted light are modulated without interrupting the optical path

• Extrinsic, where the physical stimulus interacts with the light external to the primary light path.

Intrinsic and extrinsic optical sensors can be used for touch, torque, and force sensing. For industrial applications, the most suitable will be that which requires the least optical processing. For example the detection of phase shift, using interferometry, is not considered a practical option for robotic touch and force sensors. For robotic touch and force-sensing applications, the extrinsic sensor based on intensity measurement is the most widely used due to its simplicity of construction and the subsequent information processing. The potential benefits of using optical sensors can be summarized as follow:

Immunity to external electromagnetic interference, which is widespread in robotic applications.

• Intrinsically safe.

• The use of optical fibre allows the sensor to be located some distance from the optical source and receiver.

• Low weight and volume.

Touch and tactile optical sensors have been developed using a range of optical technologies:

(a) Modulating the intensity of light by moving an obstruction into the light path.

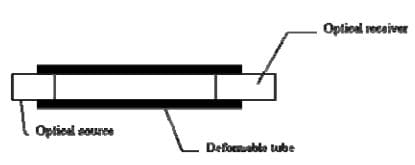

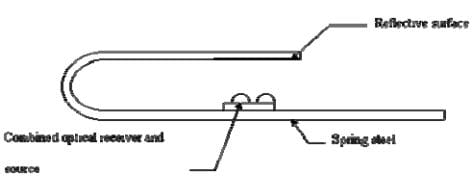

The force sensitivity is determined by a spring or elastomer. To prevent cross-talk from external sources, the sensor can constructed around a deformable tube, resulting in a highly compact sensor:

(b) Photoelasticity

Photoelasticity is the phenomena where stress or strain causes birefringence in an optically transparent materials. Light is passed through the photoelastic medium. As the medium is stressed, the photoelastic medium effectively rotates the plane of polarization and hence the intensity of the light at the detector changes as a function of the applied force. This type of sensor is of considerable importance in the measurement of slip.

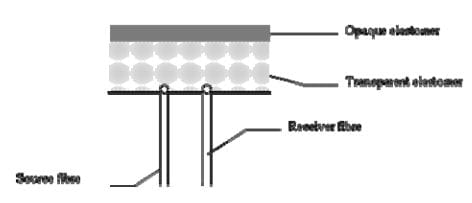

Optical fibre based sensors

In the previous section, optical fibres where used are solely for the transmission of light to and from the sensor, however tactile sensors can be constructed from the fibre itself. A number of tactile sensors have been developed using this approach. In the majority of cases either the sensor structure was too big to be attached to the fingers of robotic hand or the operation was too complex for use in the industrial environment. A suitable design can be based on internal-state microbending of optical fibres. Microbending is the process of light attenuation in the core of fibre when a mechanical bend or perturbation (of the order of few microns) is applied to the outer surface of the fibre. The degree of attenuation depends on the fibre parameter‘s as well as radius of curvature and spatial wavelength of the bend. Research has demonstrate the feasibility of effecting microbending on an optical fibre by the application of a force to a second orthogonal optical fibre.

Piezoelectric sensors

Polymeric materials that exhibit piezoelectric properties are suitable for use as a touch or tactile sensors, while quartz and some ceramics have piezoelectric properties, polymers such as polyvinylidene fluoride (PVDF) are normally used in sensors.

Polyvinylidene fluoride is not piezoelectric in its raw state, but can be made piezoelectric by heating the PVDF within an electric field. Polyvinylidene fluoride is supplied sheets between as 5 microns and 2 mm thick, and has good mechanical properties. A thin layer of metalization is applied to both sides of the sheet to collect the charge and permit electrical connections being made. In addition it can be moulded, hence PVDF has number of attraction when considering tactile sensor material as an artificial skin.

Strain gauges in tactile sensors

A strain gauge when attached to a surface will detect the change in length of the material as it is subjected to external forces. The strain gauge is manufactured from either resistive elements (foil, wire, or resistive ink) or from semiconducting material. A typical resistive gauge consists of the resistive grid being bonded to an epoxy backing film. If the strain gauge is pre-stressed prior to the application of the backing medium, it is possible to measure both tensile and compressive stresses. The semi-conducting strain gauge is fabricated from a suitable doped piece of silicone, in this case the mechanism used for the resistance change is the piezoresistive effect.

When applied to robotic touch applications, the strain gauge is normally used in two configurations: as a load cell, where the stress is measured directly at the point of contact, or with the strain gauge positioned within the structure of the end effector.

Silicon based sensors

Technologies for micromachining sensors are currently being developed world-wide. The developments can be directly linked to the advanced processing capabilities of the integrated circuit industry, that has developed fabrication techniques that allow the interfacing of the non-electronic environment to be integrated through microelectromechanical systems.. Though not as dimensionally rigorous as the more mature silicon planer technology, micromachining is inherently more complex as it is involves the manufacture of a three-dimensional object. Therefore the fabrication relies on additive layer techniques to produce the mechanical structure.

The excellent characteristics of silicon, that has made micromachined sensors possible, include a tensile strength comparable to steel, elastic to breaking point, and there is very little mechanical hysteresis in devices made from as single crystal, a low thermal coefficient of expansion.

To date it is apparent that microengineering has been applied most successfully to sensors. Some sensor applications take advantage of the device-to-device or batch-tobatch repeatability of wafer-scale processing to remove expensive calibration procedures. Current applications are restricted largely to pressure and acceleration sensors, though these in principle can be used as force sensors. As the structure is very delicate, there still are problems in developing a suitable tactile sensor for industrial applications.

Smart Sensors

The most significant problem with the sensor systems discussed so far is that of signal processing. Researchers are therefore looking to develop a complete sensing system rather than individual sensors, together with individual interfaces and interconnections. This allows the signal processing to be brought as close as possible to the sensor itself or integrated with the sensor. Such sensors are generally termed smart sensors. It is the advances in silicon fabrication techniques which have enabled the recent developments in smart sensors. There is no single definition of what a smart sensor should be capable of doing, mainly because interest in smart sensors is relatively new. However, there is a strong feeling that the minimum requirements are that the sensing system should be capable of self diagnostics, calibration and testing. As silicon can be machined to form moving parts such as diaphragms and beams, a tactile sensor can in principal be fabricated on single piece of silicon. Very little commercial success has been obtained so far, largely due to the problems encountered in transferring the technology involved from the research laboratory to industry. In all tactile sensors their is a major problem of information processing, and interconnection. An array has 2n connection and individual wires, any reduction in interconnection requirements is welcomed due to ease of construction and increased reliability. A number of researchers have been addressing the problem of integrating a tactile sensor with integral signal processing. In this design the sensor‘s conductive elastomer sheet was placed over a substrate. The significant feature of this design is that the substrate incorporated VLSI circuitry so that each sensing element not only measures its data but processes it as well. Each site performs the measurements and processing operations in parallel. The main difficulty with this approach was the poor discrimination, and susceptibility to physical damage However, the VLSI approach was demonstrated to be viable, and alleviated the problems of wiring up each site and processing the

data serially.

Multi-stimuli Touch Sensors

It has been assumed that all the touch sensors discussed in this section respond only to a force stimulus. However, in practice most respond to other external stimuli, in particular, temperature. If PVDF has to be used as a force sensor in an environment with a widely varying ambient temperature, there may be a requirement for a piece of unstressed PVDF to act as a temperature reference. It is possible for a sensor to respond both to force and temperature changes. This has a particular use for object recognition between materials that have different thermal conductivity, e.g., between a metal and a polymer. If the complexity of the interpretation of data from PVDF is unsuitable for an application, touch sensors incorporating a resistive elastomer for force, and thermistors for temperature measurement can be constructed. By the use of two or more force-sensitive layers on the sensor, which have different characteristics (e.g., resistive elastomer and PVDF), it is possible to simulate the epidermal and dermal layers of human skin.