A.B. Liggins, J.B. Finlay and C.H. Rorabeck

KEYWORDS: Knee, Replacement, Polyethylene, patellofemoral, pressure

Introduction

In total knee replacements, the bearing surface of the patella is usually replaced by an ultra high molecular weight polyethylene component which articulates on a metal femoral component In any design, the degree of congruency between these two components should be high In order to reduce Interface pressures and any tendency of the patella to dislocate. In practice, patellar element wear Is associated with a large number of revisions, leading to the speculation that these have experienced unduly high Interface pressures, probably due to suboptimal levels of congruency.

Materials and Method

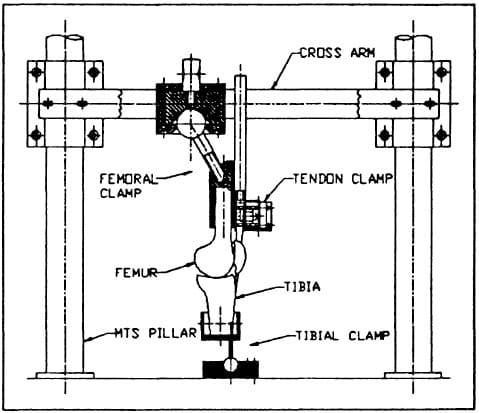

Cadaveric specimens were fined with a total knee replacement and the femur and tibia potted In bone cement. These were mounted In a test jig attached to a MTS universal testing machine, as shown In Fig I. This consisted of a secondary cross arm attached to the upright pUlars of the MTS from which the femur was suspended and a unit on the MTS table attached to the tibia via a lockable ball and socket joint. A combination of raising or lowering the secondary cross head and repositioning and locking the ball and socket unit allowed the joint to be fixed at any angle of ftexion between Oo and 90o. In order to load the patellofemoral joint. the quadriceps tendon was attached to the actuator of the MTS via a clamp. the load axis being correctly aligned by adjusting the femoral clamp.

Fig 1. TEST JIG FOR PATELLOFEMORAL LOADING

With quadriceps loading applied, patellofemorai pressure magnitude and distribution and contact stresses were recorded using both Fuji pressure sensitive film combined with Image grabbing and digitizing techniques and an experimental reftectlve photoelastlc method.

Discussion

Use of this equipment has allowed the surface stresses experienced by the polyethylene patellar element of a new knee prosthesis to be assessed and could also be applied to Intact knees. Observations from the results of these test procedures Indicate both the degree of practicality of the two methods of data collection and the viability of the patellar element design under test.

Acknowledgments

Support was provided by the Maurice Muller Foundation.