A Surface Pressure Indicator is a device or product that quantifies the pressure being exerted between two contacting surfaces. In a paper titled, “Brake Pad Surface Topography Part I: Contact Pressure Distribution”, authors Abd Rahim, Abu Bakar, and Huajiang Ouyang of the University of Liverpool and Jennifer E. Siegel of Sensor Products discussed the use of a Surface Pressure Indicator to measure static contact pressure distributions on brake pads.

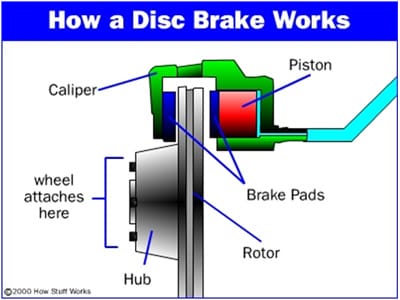

Figure 1 is a picture of a solid disc brake system. Figure 2 is a simplified schematic of the system.

Fig 1: Picture of a Disc Brake System |  Fig 2: Schematic of a Disc Brake System |

The Surface Pressure Indicator used for this work was Fujifilm Prescale® Film (formerly marketed as Pressurex®, which is referenced in the paper). Fujifilm Prescale® is a Mylar®-based film that contains a layer of tiny microcapsules. The application of force upon the film causes the microcapsules to rupture, producing an instantaneous and permanent high resolution image of pressure variation across the contact area. The color intensity of the film is directly related to the amount of pressure applied to it, the greater the pressure, the more intense the color.

In order to measure the contact pressure distributions, the film was cut to the shape of the brake pad and positioned in the pad/disc interface. Brake-line pressure was then applied to the disc brake for 30 seconds and then removed. Figures 3and 4 show films before and after brake pad testing.

Fig 3: Fujifilm Prescale® Before Testing | Fig 4: Fujifilm Prescale® After Testing |

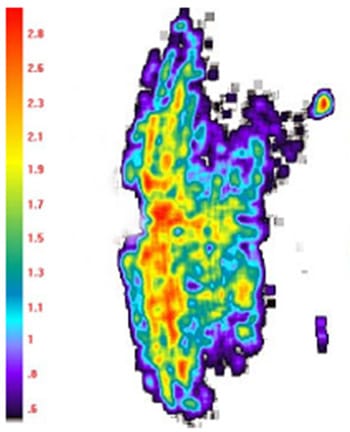

For a comprehensive understanding of the pressure distribution, the Surface Pressure Indicator film is analyzed qualitatively and quantitatively. In doing so, the Topaq® Pressure Analysis System was used. The Topaq® system is a post-process interpretive system that analyzes Fujifilm Prescale® film. The system consists of calibrated densitimetric scanner and Windows®-based software. The system is used to image and interpret the stress marks on the tested film. Figure 5 is the result of the Topaq® analysis on a brake pad.

This paper by Abd Rahim, et al, reveals that one of the reasons for variation in the contact pressure distribution is due to the brake pad surface topography. Measurements at the surface of the pads, using a linear depth gauge found that the pads have irregular and corrugated surfaces. Thus, the original FE model had to be changed to account for this. The patterns obtained by the Surface Pressure Indicator film confirmed that the original FE model was faulty.

Fig 5: Topaq® Analysis Result |

The test results also proved that the change in brake-line pressure results in different contact pressure distributions, where the higher the brake-line pressure the higher the maximum contact pressure and vice-versa. Worn pads seems to produce more concentrated contact pressure than New sets of pads, where most of the pressure is present at the outer border region of brake pads.

Finally, this paper suggests that in order to predict squeal noise generation, an FE model should be validated through static contact pressure distributions. This can be accomplished using Fujifilm Prescale® Surface Pressure Indicator film and the Topaq® system, which were proven to be very useful as a validation tools.

Additional Application Glossary entries that are related to Surface Pressure Indicator are: Surface Contact Pressure, Surface Force Mapping, Surface Force Pressure, Surface Force Profiling, Surface Pressure Distribution, Surface Profiling, Surface Stress, and Surface Stress Profiling.