In mathematics, a matrix is a rectangular array of numbers. Consider, for example, a checker board. Each block has a row and column designation. The numerical array of these block locations is an 8×8 matrix. A Matrix Pressure Sensor is a device that simultaneously measures the pressure at each contact point between two touching surfaces. This results in a pressure profile map between the two surfaces.

Figure 1 shows a grid overlaid onto an egg. Each grid intersection is a number in the matrix. A matrix pressure sensor records the pressure at each grid point (Figure 2).

|  |

| Fig 1: Grid Over Egg | Fig 2: Pressure on Grid Location |

It is widely accepted that skin sensitivity will be very important for future robots used by humans in daily life for housekeeping and entertainment purposes. A matrix pressure sensor will be useful in simulating skin sensitivity. Pressure sensing allows a robot to tell when it collides with something, or when something pushes against it. Pressure sensors can be used to measure force, and in some cases, to determine the contour of an applied force. There are many researchers trying to develop sensors to be incorporated into robotics.

The horizontal injection molding machine applies force to hold the mold closed. The plastic being injected into the mold exerts opposing pressure against the mold face. To assure that the mold does not open, the clamping pressure must exceed the injection pressure.

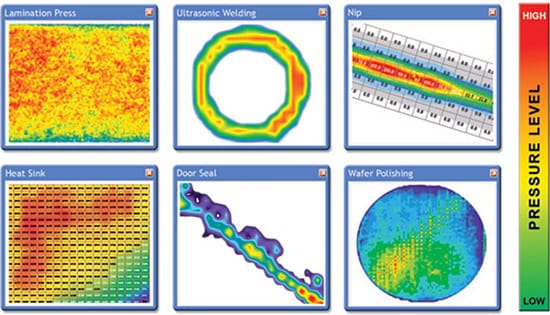

Matrix pressure sensors are useful in any applications where a pressure profile between mating surfaces is desired. Sensor Products has developed such a product called Tactilus®. Tactilus® is a matrix-based tactile surface sensor, essentially an electronic skin. It records and interprets pressure distribution and magnitude between any two contacting or mating surfaces and assimilates the collected data into a powerful Windows®-based tool kit. Each Tactilus® sensor is carefully assembled to exacting tolerances and is individually calibrated and serialized.

Fig 3: Typical applications Where Tactilus® Reveals Surface Contact Pressure

The architectural philosophy of Tactilus® is modular, allowing for portability, easy scalability, and simultaneous data collection from up to four discrete sensor pads. Tactilus® employs sophisticated mathematical algorithms that intelligently separate signal from noise, and advanced electronic shielding techniques maximize the sensor’s immunity to noise, temperature and humidity. The next generation software interface also improves the accuracy of the readings by taking into consideration the creep and hysteris effects natural to the sensors.

Tactilus® analysis can be used on any application or test where pressure lies between 0.1 PSI (0.007 Kg/cm²) to 200 PSI (14.1kg/cm²). The sensor skin is a thin flexible or rigid sheet that is densely packed with sensing points or pixels along a grid or matrix. These sensing points can be spaced as close as 2 mm (0.08″) apart and can collect data as rapidly as 1,000 readings per second. The maximum sensor array matrix is 64×64 or 4,096 sensing points.

Software features include:

- 2D, 3D, and 360 degree image rendering with extensive user control;

- Complete software library;

- Force integration and average pressure;

- Highly programmable report generator;

- Local point and region-of-interest (ROI) analysis;

- Max, minimum, and average values;

- Pressure vs. time graph and pressure histogram;

- Sophisticated calibration control; and

- Easily exportable data to Excel, ASCII or Access formats.