When two surfaces come into contact with one another, contact pressure is exerted between them. The distribution of this pressure is an important aspect of the relationship between the surfaces. Therefore, it is often necessary to map the pressure distribution between the surfaces. This is known as Contact Pressure Mapping.

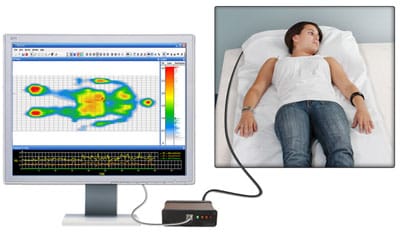

This term, Contact Pressure Mapping, can frequently be found in medical literature. Pressure damage to bedridden patients is a common complication of illness and disability. The risk is pressure ulcers or bed sores. Contact pressure mapping studies (see Figure 1) investigate high pressure areas between patients and mattresses. These studies have led to improvements in mattress materials and designs.

Fig 1: Contact Pressure Mapping Study Using the Tactilus® Bodyfitter® System

In orthopedics studies contact pressure mapping is routinely performed. These studies have found that foot orthoses can be prevented by reducing contact pressures. The Tactilus® system is effective in performing such studies.

Corey P Neu, et al, conducted a study to investigate the mechanisms by which cells convert mechanical stimulus into chemical activity. Specifically studied was superficial zone protein, a critical joint lubricant. Contact pressure mapping in whole joints was accomplished using a pressure-sensitive film (Fujifilm Prescale®). In this study, the contact areas and pressure in bovine knee joints were measured using the ultra-low-range pressure sensitive film.

Contact pressure mapping is also performed in industrial applications. For example, fuel cells have been studied using both Fujifilm Prescale® and Tactilus®. Such studies focus on the measurement of the contact pressure distribution within the fuel cell and its correlation with the applied external clamping torque. Using Fujifilm Prescale®, researchers determined that the average pressure on the membrane electrode assembly remained constant as torque was increased. It was found that the force due to increased torque was being transferred to the gaskets in the fuel cell.

Tactilus® can be used for similar studies. However, Tactilus®, tactile surface pressure mapping, allows the engineer to measure actual, real-time contact force and pressure distribution data. This technique provides time-dependent pressure information unlike pressure indicating film that only gives a maximum pressure profile. This allows the engineers to monitor the instantaneous pressure on components during the assembly process. The sensors are thin and flexible. Because of this, the sensors can be placed between two contacting surfaces with minimal affect on the overall assembly. This matrix-based technology utilizes resistive sensors (i.e., the resistance of the sensing point is proportional to pressure).