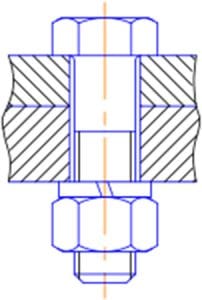

A bolted joint is a connection of two or more parts that are held together by a threaded bolt or an assembled bolt and nut. There are two main types of bolted joint designs as shown below.

Figure 1 shows a clamped bolted joint where two parts are clamped together by a bolt, nut, and washer. In a properly designed joint with appropriate torque load on the bolt, the clamped parts will see no relative motion.

Fig 1: Clamped Bolted Joint

Figure 2 shows an articulated bolted joint where the two parts are assembled using a bolt and nut. There is no clamping pressure on the parts, and they are free to move. These parts exert shear on the shaft of the bolt. Articulated joints are commonly used on hydraulic and pneumatic actuators.

Fig 2: Articulated Bolted Joint

Clamped bolted joints are often used on pipe flanges, automotive engines and chemical reactors. In all of these applications, the bolted joint has three mechanical components: the flange parts, the fasteners (bolts and nuts), and the seals or gaskets. If any part of the bolted joint assembly does not perform properly, the joint as a whole will not perform to expectations and may leak. The bolts must be of suitable strength and quantity to compress the seal and withstand the maximum hydrostatic load. Additionally, the bolts and flanges must be robust enough to prevent warpage, distortion, or separation during service. All service factors must be considered such as thermal stresses, differential expansion, external loads, and vibration.

The bolt tightening torque should be determined for each application through experimentation. A properly tightened bolt is one that is stretched, thus acting like a very rigid spring pulling the mating surfaces together. It is very difficult to directly measure the tension or preload in the fastener. However, Fujifilm Prescale® pressure indicating film allows engineers and researchers to directly measure the pressure exerted by the bolts.

Fujifilm Prescale® is a Mylar-based film that contains a layer of tiny microcapsules. The application of force upon the film causes the microcapsules to rupture, producing an instantaneous and permanent high resolution “topographical” image of pressure variation across the contact area.

Simply place Fujifilm Prescale® pressure indicating sensor film between any two surfaces that touch, mate or impact. Apply pressure, remove it and immediately the film reveals the pressure distribution profile that occurred between the two surfaces. Conceptually similar to Litmus paper, the color intensity of Fujifilm Prescale® is directly related to the amount of pressure applied to it. The color intensity is directly proportional to the applied pressure.

Tactilus® is another tool to measure forces in clamped bolted joints. The Tactilus® force indicating washer is a revolutionary new means to measure and assess bolted joint tension, design, and efficacy. Unlike traditional strain gauged load cells and force washers, The Tactilus® force sensor is extremely thin, non-invasive, and highly economical. The Tactilus® force sensor system is a valuable aid in R&D.

Upon the application of tension, the Tactilus® force indicating washer reveals precisely how much force (tensile load) is being applied at the interface of the bolt and flange surface, and how this force is circumferentially distributed.