Article: Plastic in Packaging

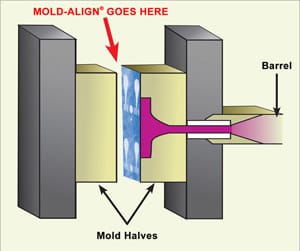

Unlike traditional methods such as bluing agents, clay and conventional carbon papers, the Mold-Align® tool instantly changes colour when placed between mould halves to reveal how pressure is distributed between the halves of the mould.

Mold-Align® captures a permanent image of pressure variation.

Bluing agents, when applied to one half of the mould, will transfer to the other if there is any contact at the parting line, but will not distinguish between high and low pressures. Quality suffers and production time may be lost due to improper troubleshooting of flash shorts and burns.

Mold-Align® is placed between the mould platens on the parting line, which are then closed using minimal clamp tonnage. It is then removed and the image inspected for pressure distribution and void spots.