Article: Aluminium International Today

To optimise the weld and prevent defects, the horn and anvil must be precisely aligned during set-up so that the horn exerts uniform pressure across the entire weld area. An economical and precise procedure that will ensure this outcome uses Pressurex® pressure indicating sensor film.

Use of Pressurex® during the set-up helps ensure proper contact pressure and alignment between the horn and anvil, which results in welds of greater bond strength and aids in reducing rejected product and so lower cost.

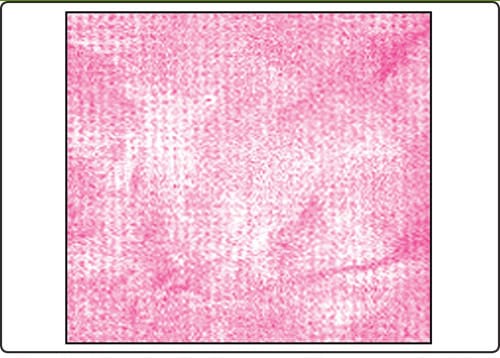

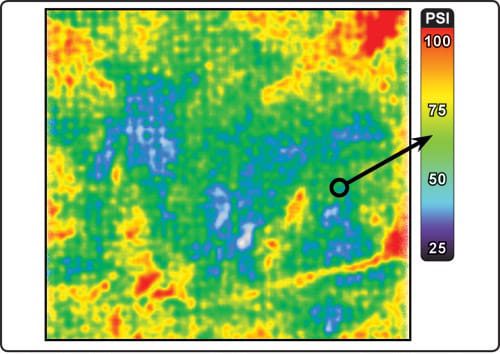

Pressurex® reveals the distribution and magnitude of pressure between any two contacting surfaces. When placed between the horn and the anvil of the ultrasonic bonder, the film instantaneously and permanently changes colour directly proportional to the actual pressure applied. The precise pressure magnitude is then easily determined by comparing colour variation results against a colour correlation chart. If desired, the film can be further analysed. Pressurex® film is thin (100-200mi) and flexible, which enables it to conform to curved surfaces. These pressure maps show that there are pressure variations across the “weld zone” which can result in less than optimal weld strength. Such variations are generally caused by lack of alignment between the horn and anvil or by dirt or residue on the horn. To fix these conditions during set-up: First, turn on the ultrasonic welder and set the supply air pressure. Place a flat gauge on the contact point of the anvil to simulate the thickness of the parts to be welded. Lower the horn onto the flat gauge to calibrate the height setting. Align the horn tip and the anvil. Place Pressurex film on top of the flat gauge and lower the horn to exert light pressure on the film. Lastly, adjust the horn tip as needed through repeated set-ups with the sensor film (Fig 1). The set-up is correct when the pressure density on the film is uniform in colour.

Fig 1 Setting up contact pressure distribution for ultrasonic welding

|  |

| Colour variation on Pressure film reveals contact flaws | Pressure profile after image analysis |