Article: NDT Marketplace

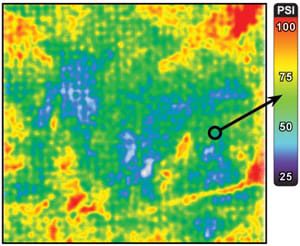

Sensor Product’s Pressurex® film is an easy-to-use tool that reveals the distribution and magnitude of pressure between any two contacting surfaces. Ultrasonic welding, which uses high-frequency ultrasonic acoustic vibrations to create solid-state welds, is becoming more popular for composite materials such as carbon fiber. To optimize the weld and prevent discontinuities in ultrasonic welding, the horn and anvil must be precisely aligned during setup so that the horn exerts uniform pressure across the entire weld area. An economical and precise procedure that will ensure this outcome involves the use of Pressurex® pressure indicating sesnor film. Routing use of Pressurex® during the setup of ultrasonic welders helps ensure proper contact pressure and alignment between the horn and anvil, which results in welds of greater bond strength and aids in reducing rejected products and lowering base factory cost. When placed between the horn and the anvil of the ultrasonic bonder, the film instantaneously and permanently changes color directly proportional to the actual pressure applied. The precise pressure magnitude is then easily determined by comparing color variation results to a color correlation chart (conceptually similar to interpreting Litmus paper). If desired, the film can be further analyzed. Pressurex® is extremely thin (100 to 300 μm) and flexible, which enables it to conform to curved surfaces.