Article: Iron & Steel Today

Headquartered in New Jersey and established in 1990, Sensor Products Inc manufactures and distributes tactile pressure sensing solutions. This includes developing Sigma-Nip®, which yields high resolution for viewing nips of all configurations.

Sensor Products Inc has introduced Sigma-Nip®, an electronic nip analysis system for steel mills that measures roller profiles and diagnoses roll alignment with speed, cost-effectiveness and accuracy. Capabilities include instantaneously measuring loading uniformity to reveal misalignment and related problems. Operators can then make adjustments ‘live’ for contacting rollers of virtually all dimensions and surfaces.

According to Ted Young, steel industry consultant to Sensor Products Inc on many occasions when a mill experiences strip run-off, the determination is generally focused on the rolls involved. “However, this problem can be caused by a number of circumstances not necessarily roll-related” he suggests. Problems such as end-to-end PSI non-uniform loading, misalignment of the roll set and premature loss of crown or roll surface deformation can be the problem areas. Sigma-Nip® can identify these problems, diagnose the specific circumstances and offer corrective actions.”

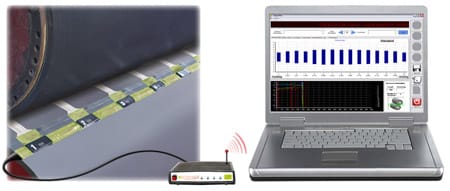

Sigma-Nip® positioning on a roller set and transmitting to a laptop provides real-time nip analysis.

Each active sensor within the unit is capable of handling 10,000 PSI in nip intensity. The system, which is already used by the pulp, paper and converting industries, has been modified to provide a one-of-a-kind solution for diagnosing problems in the steel industry within cold and finishing mills, where nipped rolls are engaged and applied. Sigma-Nip®, which is easy to use, portable and cost efficient, is claimed to make carbon paper analysis methods outmoded.

The active sensing area of Sigma-Nip® is very

compact, leading to high resolution measurement.

With Sigma-Nip®, nipped rolls are verified for nip uniformity instantaneously. Sensors capture data and record nip width readings while being viewed on a laptop containing Windows-based software. This allows technicians to see ‘five’ precisely what the strip sees in operation. Adjustments needed for uniformity are made by the operator while the nip is closed (static mode). Operators can then adjust the loading to secure within .001 in end to end loading uniformity. The ultimate benefit of this analysis is to determine if there are problems in alignment, potential strip run-off, roll surface deformation, need for crown corrections and/or adjustments for loading mechanism integrity.

The 168 microscopic sensor points that comprise each finger are densely affixed within an 840mm active sensing area. This yields nip width measurements with fine resolution. The system is also durable, while minimal computer knowledge or training is needed, since the system prompts the user through the few steps needed for installation and setup. Software enhancements include a comparison mode, where up to three nip width readings can be viewed simultaneously and an alignment tool, which instantly draws a line to indicate nip uniformity variations.

Sigma-Nip® is recommended for continuous maintenance of rollers. Data that has been stored and exported to Microsoft Excel is easily reviewed and archived. Strip control is improved as evenly loaded roller sets are much less likely to cause strip problems (strip drifting), which result in costly down time. Strip run off is prevented, as Sigma-Nip® can detect and correct this problem prior to startup. Reader Reply No.34