Article: Micronews

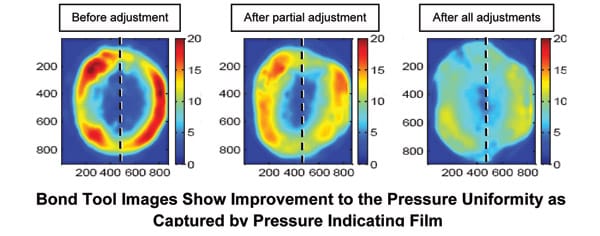

Pressurex® film from Sensor Products Inc. is a quick, accurate and economical way to detect and correct pressure variations which can result in flaws (defects) in the wafer bonding process. When placed between contacting surfaces, it instantaneously and permanently changes color directly proportional to the actual pressure applied. With Pressurex®, variations in pressure that lead to imperfections (or irregularities) in the bonding process can be accurately detected and corrected — improving yield, decreasing scrap, and boosting productivity. Wafer-to-wafer bonding has become an enabling semiconductor technology in industries such as 3D packaging, MEMS, MOEMS, and SOI. Pressurex® is being used across a wide range of bonding technologies, including metal eutectic, anodic, fusion, metal diffusion, glass frit, and polymer adhesive bonding. Micralyne Inc. uses Pressurex® to adjust the compression exerted by their bonding tools. Early testing of bonding results analyzed with the film reveals a donut shaped high pressure ring with relatively little pressure applied to the center (left on the picture). After a series of adjustments the final result is a more uniform distribution of pressure (right on the picture).