Article: Medical Device Technology

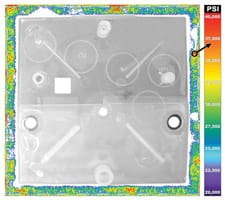

Pressurex® is a thin, flexible, Mylar-based sensor film that instantly captures and permanently records pressure distribution and magnitude between any two mating or contacting surfaces. After being clamped up and placed around the parting line of a mold, the sensor reveals whether the pressure is evenly distributed.

“With molds becoming more complex and being exposed to high pressures, it is a superior tool to bluing agents, which mold makers traditionally use,” says John Bozzelli, owner of Injection Molding Solutions, who uses Pressurex to demonstrate good or bad parting line mating, and open or closed vents in his consulting and training services”

Pressurex® reveals pressure from 2 – 43,200 PSI and is available in eight different pressure ranges, with medium and high pressure being the most commonly used for injection molding applications. When placed between two contacting surfaces, the film instantaneously and permanently changes color directly proportional to the actual pressure applied. Precise pressure magnitude is easily determined by comparing the resultant color intensity to a color correlation chart (conceptually similar to interpreting Litmus paper). No training or instrumentation is required.