Article: IUV Magazine

Pressurex® film is an economical, accurate and easy-to-use tool that reveals the distribution and magnitude of surface contact pressure in battery lamination and calendaring presses. Difficult to detect pressure variations across the surface of battery laminators and calendar presses can be easily detected and corrected through use of the sensor film.

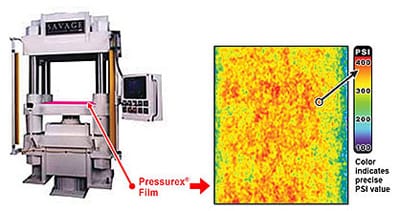

When placed between lamination platens or calendar rolls, Pressurex® instantaneously and permanently changes color directly proportional to the actual pressure applied. Precise pressure magnitude is then easily determined by comparing the resultant color intensity to a standardized color correlation chart (conceptually similar to using Litmus paper). No training or instrumentation is required.

Pressure Profile Across a Battery Lamination Platen

Pressurex® helps to ensure uniform alignment of mating rollers and lamination platens. If the contacting rollers and platens are not parallel, uneven compression could result in delamination during battery discharge or poor contact between the electrodes and their current collectors. Electrodes could also have uneven thicknesses reducing contact area, which is a major problem for cylindrical Li-ion and Li/MnO2 cells and prismatic cells. In addition, uneven contact in heat seal presses could cause leakages in pouch cells.

All four battery types that require a lamination stage can be manufactured and monitored with Pressurex®, including:

- Polaroid P-80, Zinc-Manganese Dioxide ((Zn/MnO2) Cells – The contents of the battery are laminated within a “coffee-bag” material using a bag heat sealer.

- Lithium-Manganese Dioxide (Li/MnO2) Pouch cells – Similar to the P-80 battery, these cells are laminated into bags. In addition, the current collector for the lithium is laminated to the inside of the bag through using a small pneumatic or hydraulic press with heated platens.

- Lithium-ion (Li-ion) Polymer Cells — The positive and negative electrodes for these cells are cast from slurries containing the active ingredients, binders, and conductive media. They are then laminated to their expanded-metal current collectors and a separator layer is also cast. Then, the positive and negative electrodes are laminated to the separator using either heated double-roll laminators or parallel-platen presses.

- Metal-Air Cells — Metal-air cells utilize an air electrode consisting of a carbon layer, nickel mesh, a second carbon layer, and Teflon film. These four layers are laminated together in a continuous web process using a laminating press.

During calendaring operations, positive and negative electrodes for Li-ion cells and the MnO2 electrode in Li/MnO2 cells are densified using calendering equipment. The electrodes are passed through heavy calender rollers in a continuous process.

Pressurex® is virtually indispensable for manufacturing process control and machine/component inspection. “Snapshot” imaging results of the film can be used as a control to compare processes and tools, making it ideal for Six Sigma and other closely monitored high performance manufacturing operations. The spatial resolution of the film is very fine (dense) revealing minute surface defects and other imperfections. Additional pressure analysis of the exposed film is available, if desired, through Sensor Products Inc.

Pressurex® measures pressures from 2 – 43,200 PSI (0.14 – 3,000 kg/cm2). The pressure indicating film is very thin (4 mil or 8 mil thick) and can be hand or laser-cut to any size or dimension. It is flexible and conforms to curved surfaces and invasive intolerant environments. The film is coated on a Mylar sheet and is physically similar to a standard sheet of paper. Pressurex® is available in eight pressure ranges. For a free sample in your desired range, contact Sensor Products Inc. at 1.973.884.1755 (USA), email [email protected] or visit their website at www.sensorprod.com/sample for their entire line of products and applications.

About IUV Magazine:

Industrial Utility Vehicle & Mobile Equipment magazine is dedicated to engineering, technical and management professionals as well as dealers and fleet managers involved in the design, manufacture, service, sales and management of lift trucks, material handling equipment, facility service vehicles and mobile equipment, golf cars, site vehicles, carts, personal mobility vehicles and other types of special purpose vehicles. Each issue of IUV features articles about new product development, technology, industry news and trends.