Article: Modern Plastics Worldwide

The only parts that count are the ones that meet quality standards, and keeping pressure evenly distributed across a mold’s parting lines is one of the many critical tasks to get those good parts molded. An option to bluing agents, the long established means of gauging pressure distribution, comes in the guise of Pressurex®, a thin flexible plastic film that captures and permanently records pressure distribution and magnitude between any two mating or contacting surfaces—such as mold halves.

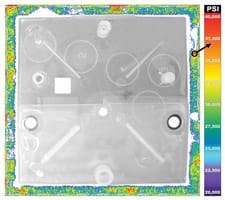

Sensor Products Inc. (Madison, NJ) makes and markets Pressurex®, which is similar in appearance to ordinary paper and is available in thicknesses of 4 or 8 mils. It is available in sheets or rolls that can be cut to size. After being clamped up and placed around the parting line of a mold, the mold can be closed. When placed between the two contacting surfaces, the film permanently changes color directly proportional to the actual pressure applied. A user then compares the resultant color intensity to a color correlation chart—akin to measuring acidity with Litmus paper. Pressurex® reveals pressure from 2-43,200 PSI (0.14-3000 kg/cm²) and is available in eight different pressure ranges, with medium and high pressure most commonly used for injection molding.

“In injection molding, Pressurex® confirms that parting lines are mating properly to prevent flash, and that the vents are open allowing for proper filling of the mold cavity,” according to John Bozzelli, owner of Injection Molding Solutions (Midland, MI), who uses Pressurex® in his consulting and molder training services. (Ed.: Bozzelli also made MPW’s list of the industry’s most Notable Processors.)