Article: Tube News

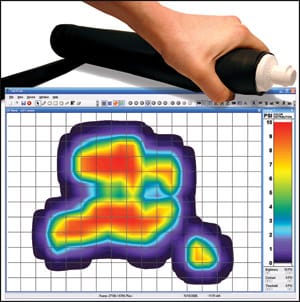

Tactilus® characterizes pressure distribution and magnitude

A system that quantitatively measures how users dispense products with tube packaging is available as an aid in evaluating where and how a tube fatigues, as well as when labels or appliqués delaminate. This testing can help design engineers improve the functionality and ergonomics of a container by improving the grip and contact area. The Tactilus® Tube testing system comprises a matrix-based tactile surface sensor element, software, and electronic hub that plugs into any Windows-compatible PC. The sensor element is essentially an electronic skin that records and interprets pressure distribution and magnitude between any two contacting or mating surfaces. An electronic hub transmits the data collected into a Windows-based software tool kit. The sensor element encases a tube. When pressure is exerted upon the tube, a pressure profile rapidly illustrates exactly where and how much force is being applied. The unit reveals the time and force required to expel contents from a tube, and gives insight into squeezing techniques used by different demographic segments.