Article: Rubber, Fibers, Plastics International

Mini Sigma Nip® sensors and software provide detailed analysis of nip condition

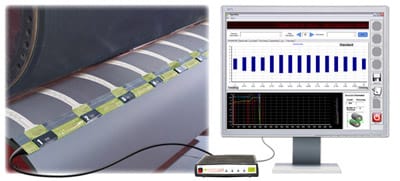

Sensor Products Inc. has introduced a new device called Mini Sigma-Nip®, an electronic nip analysis system which measures roller profiles and diagnoses roll alignment. While its �bigger brother� Sigma-Nip® is suitable for the characterization of profiles for large rolls, Mini Sigma-Nip® provides a solution for measuring nip widths of rolls with circumferences smaller than 51cm/20�. The company says, that for the first time ever large bone hard rolls with narrow contact areas can also be characterized by an electronic system.

Mini Sigma-Nip�s sensors capture data and record nip width readings while being viewed on a laptop containing its Windows based software. Adjustments to load are made in real time while the sensors are in the closed, (non-rotating) nip. Problems with alignment, skewing, and crown deficiencies are quickly exposed. Software enhancements include a Comparison Mode, where up to three nip width readings can be viewed simultaneously, and an Alignment Tool, which instantly draws a line to indicate nip width variations.

In Mini Sigma-Nip®, the 168 microscopic sensor points that comprise each finger are densely packed within a smaller (8.4 cm/3.3 in) active sensing area. This yields nip measurements with 2.5 times the resolution of the larger Sigma-Nip®, which is a powerful new diagnostic tool that is principally used for pulp & paper manufacture and some converting operations.

In Mini Sigma-Nip®, the 168 microscopic sensor points that comprise each finger are densely packed within a smaller (8.4 cm/3.3 in) active sensing area. This yields nip measurements with 2.5 times the resolution of the larger Sigma-Nip®, which is a powerful new diagnostic tool that is principally used for pulp & paper manufacture and some converting operations.