Article: Automotive Products Finder (India)

Tactilus®, a real-time dynamic electronic pressure mapping system, makes for an effective quality control and failure analysis

During the design process, it is of-ten necessary to calculate the distribution and magnitude of pressure between two contacting, mating or impacting surfaces. Quite often these surfaces are not easily accessible, making it difficult to take proper impact measurements. To ensure that accurate readings can be taken between pressure points, Sensor Products Inc. has come up with the Tactilus® real-time dynamic electronic pressure mapping system, which make for a more effective quality control and failure analysis.

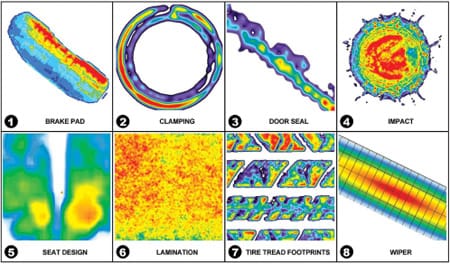

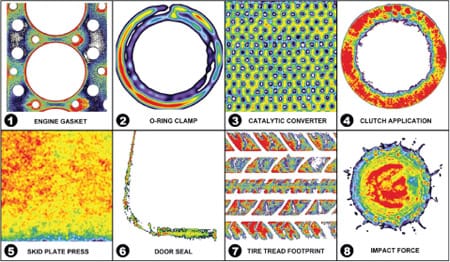

Commonly used throughout the automotive industry to quickly and accurately map pressure distribution between any two contacting surfaces, Tactilus® is increasingly viewed as an effective and cost efficient way to quickly assist engineers in R&D, failure analysis and quality control efforts. In fact, OEMs and aftermarket manufacturers and distributors employ the systems for a variety of automotive applications. The most common applications and corresponding examples revealing how real-time pressure mapping aids the automotive industry and includes brakes, clamping applications, door seals, impact producing components, seats, tire tread, wipers, etc.

In brakes, Tactilus® enables verification of consistent compressive force across brake shoe. It assesses squeal and fugitive noise. Useful for quality control in caliper design and development. The system also authenticates circumferential uniformity on cylindrical clamps and determines appropriate tensioning. Tactilus® confirms uniform sealing of moldings and weather stripping (door seals) for fuel efficiency and road noise reduction. In case of impact issues, Tactilus® determines the location and force of impact during airbag deployment and controlled crash tests. In case of seats, the system enables accessing of critical points of pressure to aid in more comfortable seat design.

Tactilus® offers assistance in maintaining desired plate pressure for the reduction of scrap rates in case of laminations. Tactilus® evaluates congruity of footprint and rib patterns of tires. This is helpful in research of tread wear patterns and development of rubber compounds and tread designs. When it comes to wipers, Tactilus® evaluates for even surface pressure to maximize wiper effectiveness.

Says Vadim Shalyt, Sensor Products� senior applications specialist: “Tactilus® technology particularly lends itself to diverse automotive applications. Not only do the systems evaluate such a range of pressures with ease, but save time by providing information immediately with in-depth statistical data. These systems are ideal for assembly line assessment for OEMs and aftermarket product manufacturers.”

Evaluating tactile contact pressures in real-time, the Tactilus® system comes equipped with all components necessary to collect data for comprehensive analysis, including a matrix-based sensor mat, controller, and user-friendly software. Not only is Tactilus® conformable to highly curvaceous surfaces and intolerant environments, but is portable and runs on a standard laptop computer.

The upgraded feature-rich software for Tactilus® offers 2-D and 3-D imaging, region-of-interest viewing, longitudinal and latitudinal analysis, graphical displays of data in bar, pressure versus time, line scan, histogram and isobar charts, statistical analysis of average/minimum/maximum pressures, total force over any selected area and more. The data may also be exported to virtually any third party software.