Article: Connectingindustry.com

Sensor Products Inc. introduces Pressurex®, a tactile force indicating sensor film. The sensor comes in the form of a large thin sheet, actually a film, physically similar to this page. When placed in between impacting or mating surfaces, the sensor film instantaneously and permanently changes color. The intensity of this color is proportional to the amount of force applied allowing the user to actually quantify the stress characteristics across the surface. Precise PSI (kg/cm²) can be determined by comparison of the sensor film to a color calibration chart (conceptually similar to interpreting Litmus paper), or by using one of several imaging systems that Sensor Products supplies.

Sensor Products Inc. introduces Pressurex®, a tactile force indicating sensor film. The sensor comes in the form of a large thin sheet, actually a film, physically similar to this page. When placed in between impacting or mating surfaces, the sensor film instantaneously and permanently changes color. The intensity of this color is proportional to the amount of force applied allowing the user to actually quantify the stress characteristics across the surface. Precise PSI (kg/cm²) can be determined by comparison of the sensor film to a color calibration chart (conceptually similar to interpreting Litmus paper), or by using one of several imaging systems that Sensor Products supplies.

Pressurex® technology is a valuable aid in R&D and QC/QA in electronic packaging. Determining pressure distribution within a laminating press for multilayer printed circuit boards and revealing uneven pressure distribution across the nip of rollers on a dry film laminator are just some of the capabilities of Pressurex®. The film also is useful in detecting imperfections within the nips themselves. When manufacturing hybrid circuits, the sensor film reveals inconsistencies in resistor thickness across large area substrates. Uniformity problems are clearly revealed during thermocompression in the TAB process and designing heat sinks.

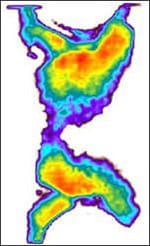

Pressurex® aids significantly in performing thermal analysis between a heat sink (transistor) and heat source. Examining a typical heat sink/heat source interface reveals microroughness and planarity problems that can not be detected by the human eye alone. Since the force films are quantifiable, an engineer can determine exactly how much pressure is occurring at any point of the interface surface, helping balance the tradeoff between greater thermal conductivity (more tension at the interface) and substrate cracking (overtensioning of the mounting bolts).