Article: Ingenieurs de l’Automobile

Each Tactilus® sensor is carefully assembled to exacting tolerances and is individually calibrated and serialized. The architectural philosophy is modular, allowing for portability, easy scalability, and simultaneous data collection from up to four discrete sensor pads. Tactilus® employs sophisticated mathematical algorithms that intelligently separate signal from noise, and advanced electronic shielding techniques maximize the sensor’s immunity to noise, temperature and humidity. Extensive calibration techniques ensure accuracy during testing, while also saving valuable time by avoiding extensive calibration procedures. The next generation software interface also improves the accuracy of the readings by taking into consideration the creep and hysteris effects natural to the sensors.

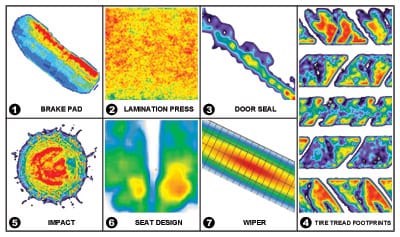

Any application or test where pressure lies between 0.1 PSI (0.007 kg/cm²) to 200 PSI (14.1 kg/cm²) will benefit from a Tactilus® analysis. The customization capabilities include sensors that will conform to difficult shapes like door seals, seats, wipers, tires, and many others.

Tactilus® is a tool kit designed by Sensor Products Inc. that consists of an electronic sensor element (« skin »), signal conditioning electronics and software. The sensor skin is a thin flexible or rigid sheet that is densely packed with sensing points or pixels. These sensing points can be spaced as close as 2 mm (0.08′) apart and can collect data as rapidly as 1,000 readings per second.