Article: Race Tech

A tactile pressure indicating sensor film that can observe interface stresses between contacting or mating components including tires and gaskets

Much of the success of the NASCAR-winning Joe Gibbs Racing Team depends on its mechanics and engineers who search for new products to keep its cars in top condition. With the clock ticking for trophy competition on the weekend, only the most effective diagnostic products are used. Recently, Todd Bowland, an engineer with the Joe Gibbs Racing Team, discovered Pressurex®, a tactile pressure indicating sensor film from Sensor Products.

“It is providing me with a solution that is easy to use, quick, and cost-effective,” says Bowland. “It’s the only tool I have ever seen for actually observing the interface stresses between contacting or mating components.”

Pressurex® film measures pressure from 2 – 43,000 psi (0.14 – 3,000 kg/cm²). When placed between two contacting surfaces, the film instantaneously and permanently changes colour which is directly proportional to the actual pressure applied. Precise pressure magnitude is easily determined by comparing the resultant colour intensity to a colour correlation chart which is conceptually similar to interpreting Litmus paper. No training or instrumentation is required.

Pressurex® comes in the form of a thin Mylar sheet, physically similar in thickness to paper. The sensor is very thin, allowing it to conform to curvaceous surfaces or invasive intolerant environments.

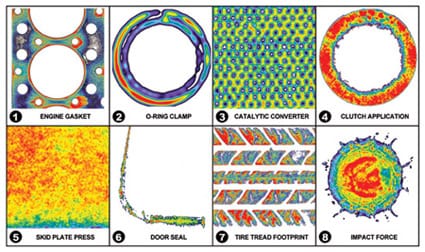

A common application is the engine gasket to evaluate adequate torque and consistency of junctions in head, valve cover, oil pan and intake/exhaust manifold gaskets and o-rings. Other applications include clamping, catalytic converter canning and brakes and clutches that can verify consistent compressive force across brake shoe or clutch surface. It is also used for tyre tread footprints, evaluating the congruity of footprint and rib patterns. It is also helpful in the research of tread wear patterns and development of rubber compounds and tread designs.