Don’t Cut Down on Quality Control of Nip Rollers During Tough Economic Times

Mohawk Fine Papers uses Pressurex® Sensor Film To Extend Roll Life, Maximize Yields, and Improve Quality

Madison, NJ (USA) – November 11, 2009 – During tough economic times it is tempting to reduce quality control to cut costs. However Dolph Beyer, an engineer with Mohawk Fine Papers, asserts doing this is actually counterproductive. He has determined using Pressurex® pressure indicating sensor film as a quality control tool actually decreases costs while significantly improving product quality.

“By taking nip impressions with pressure indicating film every couple of weeks we have extended roll life by a few months in many cases,” says Mr. Beyer. ”This quality control measure not only lowers costs for the replacement of these covers, but also minimizes equipment downtime.”

Pressurex® reveals pressure from 2 – 43,200 PSI (0.14 – 3,000 kg/cm²). When placed between contacting rollers, the sensor film instantaneously and permanently changes color directly proportional to the actual pressure applied. Precise pressure magnitude is then easily determined by comparing color variation results to a color correlation chart (conceptually similar to interpreting Litmus paper). Variations in pressure that lead to defects in papermaking, converting and printing can be quickly and accurately detected and corrected — improving yield, decreasing scrap, and increasing productivity.

Figure 1. Pressurex® is placed on the roller at Mohawk Fine Papers before closing the nip.

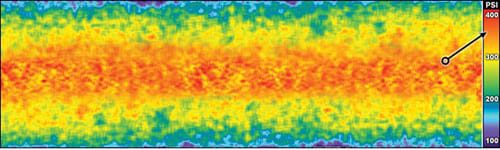

Figure 2. Pressurex® reveals variation in nip contact pressure which can be easily quantified.

-MORE-

Quality Control of Nip Rollers – 2

By examining pressure variations in the nip, corrections in alignment and crown profiles can be made. The film is effective on virtually all roller compositions and surfaces. A visual pressure mapping profile of an engraved pattern or drilled roll can be effortlessly produced that exposes minute surface defects and other imperfections.

Pressurex® reveals nip pressure magnitude and distribution.

Pressure indicating sensor film is cited by Mr. Beyer as being especially helpful with calendar rolls, which are swim rolls that have mechanisms to allow the center of the rollers to exert a different level of pressure. “Similar to crown rolls, swim rolls need to be carefully monitored to ensure even and exacting pressure is being applied to achieve optimum nip conditions,” says Mr. Beyer. “We use the film to create just the right nip and improve the roll shape and crown to deliver better sheet uniformity.”

Mohawk Fine Papers uses Pressurex® to take static nip impressions on their press section and dynamic nip impressions on their calendars. Dynamic nip impressions are inspected for uniformity and static nip impressions for uniformity and nip pressure. Image results of Pressurex® are archived and used as a control to compare tools and processes.

Pressurex® is extremely thin (4 to 8 mils) and flexible, which allows it to conform to curved surfaces. It is ideal for invasive intolerant environments and tight spaces not accessible to conventional electronic transducers. While recommended for tests in non-operating conditions, the sensor film can be used at temperatures exceeding 200 ºF (93 ºC) for brief intervals.

-END-

About Sensor Products Inc. (USA)

Headquartered in New Jersey and established in 1990, Sensor Products Inc. is a world leader in the manufacture and distribution of tactile pressure sensing solutions. Their customized and off-the-shelf products are installed within all of the Fortune 500 industrial companies as well as thousands of smaller manufacturing firms. Their sensors are used in applications as diverse as tire testing to semiconductor manufacturing and from R&D labs to space missions. Additionally, Sensor Products provides in-house and on-site stress and pressure mapping analysis, as well as a variety of regional technical seminars.

About Mohawk Fine Papers Inc.

Recognized for its technical innovation and environmental focus, Mohawk Fine Papers Inc. is the largest privately-held premium paper manufacturer in North America.